|

Ozone is often used

by reef aquarists to "purify" the water. To most

aquarists that means making the water clearer, and it certainly

does that in many cases. How to optimally accomplish that

task without risking the aquarium inhabitants' or the aquarist's

health, however, is not always obvious. This article is the

second in a series that discuss the details of ozone and its

use in reef aquaria:

Ozone

and the Reef Aquarium, Part 1: Chemistry and Biochemistry

Ozone and the Reef Aquarium, Part 2: Equipment and Safety

Ozone and the Reef Aquarium, Part 3: Changes in a Reef Aquarium

upon Initiating Ozone

The series' first

article detailed what ozone is and how it reacts with

seawater. It also related ozone's perceived benefits to the

actual chemical and biochemical changes that it can cause.

In a sense, it provided the mechanistic framework for understanding

why ozone does what it does and served to help aquarists understand

its limitations.

This second article builds on these principles, using the

mechanistic information about ozone's reactions to discuss

how it is best employed in an engineering sense.

The sections are:

Introduction

Figure 1 shows a schematic of how

ozone is typically used in a reef aquarium. Some of these

steps may be eliminated in particular applications, but aquarists

should understand that by doing so they may be using other

than optimal procedures. Subsequent sections of this article

go through these steps one by one, detailing why each is important,

how they are accomplished and the limitations to safe and

effective ozone use.

|

Figure 1. A schematic of ozone's use in a typical

reef aquarium system.

|

The process starts with an air source, usually a normal aquarium

air pump. The air is often passed through a dryer where a

hygroscopic material such as silica is employed that removes

much of the water from the air; this is referred to as an

air dryer. After passing out of the dryer tube and through

an air check valve to prevent water from backing up into the

system, the air enters the ozone generator itself. Drying

the air in advance enhances the ozone generator's effectiveness.

After the ozone-laden air passes out of the ozone generator,

it is sent to a mixing chamber where aquarium water and the

gas are mixed well and are kept in contact for at least a

few seconds. Aquarists often use skimmers or specially made

ozone reactors for this purpose. Selection of suitable materials

for these devices is a concern as the ozone

can degrade some types of plastic, rubber and tubing.

Inside the contact chamber, the ozone reacts with many different

chemicals in the seawater. Most of the benefits that accrue

from ozone's use must take place in this chamber. Inside it,

for example, the water is made "clearer" as certain

light-absorbing pigments in dissolved and particulate organic

molecules are destroyed, generally by oxidation.

Not all of the products of ozone's reaction with aquarium

water are beneficial, however. Water leaving the contact chamber

is optimally passed over activated carbon sufficient to remove

the remaining ozone produced oxidants. The carbon breaks down

most of these potentially hazardous oxidants before they enter

the aquarium. The air passing out of the reactor also contains

ozone and is also best passed over activated carbon to reduce

the concern for airborne ozone's toxicity.

In order to ensure that not too much ozone or its byproducts

enters the aquarium, aquarists monitor the aquarium water's

ORP

For those aquarists using a small amount of ozone, monitoring

may be adequate. For those aquarists using large amounts of

ozone, an ORP controller may be important. It can be used

to shut off the ozone if the ORP rises above a set point (that

point being either an emergency shut-off point that is rarely,

if ever achieved, or a target ORP where the generator is actually

running only part of the time and only when the ORP controller

says that ORP needs to be raised to the set point).

Air Flow

Most ozone applications used by reef

aquarists employ an air pump as their initial air source.

While some units (such as one by Enaly)

combine an air pump with an ozone generator, that is not the

normal setup. Pressurized air in a cylinder or pumped tank,

or even pure oxygen, can also be used, but due to their added

expense those methods are unlikely to be used by most hobbyists.

The only situation where aquarists might not use an air pump

would be if the air/ozone mixture were being sucked through

the ozone generator into a venturi, a common device on many

skimmers, that allowed it to then enter a reaction chamber

of some sort. In general, this is not the most common application,

though, as an air dryer may put too much back pressure to

allow a venturi to adequately draw in enough air.

How much air is enough? Luckily, it doesn't seem to matter

too much. Sanders, a longstanding manufacturer of ozone equipment

for aquarists, suggests on its website

that air flow should be 50-500 liters per hour for ozone generators

producing from 2 to 300 mg of ozone per hour. Larger units

producing up to 2000 mg ozone per hour require airflow of

100 to 1000 liters per hour. Bear in mind that if the air

is sent into a pressurized reaction chamber of some sort (as

opposed to a skimmer), or even through a drying tube, substantial

back pressure may reduce the air flow considerably below the

rated maximum for an aquarium air pump.

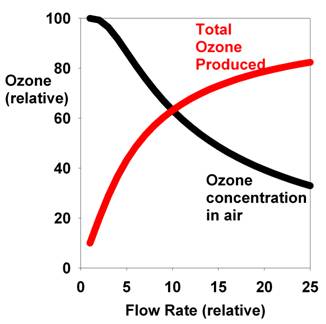

Scientific studies have found that the air flow through corona

discharge ozone generators does not seem to alter the production

of ozone significantly unless the flow is slow enough that

ozone produced inside the generator does not escape before

it has a chance to be broken down by reactive species in the

corona discharge (discussed below). One group1 fitted its

results to the equation shown below:

X

= Xo(1-e-a/F)

where X is the ozone concentration in the ozone generator's

output in units such as mg/L, "a" is a constant

relating to the unit's power, F is the flow rate and Xo

is the maximum ozone concentration at low flow rates. The

flow rate's effect on the ozone concentration is shown in

Figure 2. It should be noted, however, that even if the ozone

concentration is lower at higher flow rates, the total ozone

produced is not. To find the rate of ozone production (in

units such as mg/hour) requires multiplying the ozone concentration

in the air produced by the rate of air flow (F):

Ozone

Production Rate = FXo(1-e-a/F)

The flow rate's effect on total ozone output is also shown

in Figure 2. Note that it actually increases steadily with

increasing flow rate. This effect is easy to understand. Higher

flow sweeps away the newly produced ozone before it has a

chance to break down again inside the generator and replaces

it with fresh air containing O2, which

is then ready to produce more ozone. Unfortunately, I do not

know exactly where on these sorts of flow rate vs. ozone production

curves that typical commercial aquarium ozone generators fall

(or if they even follow this exact same relationship). Sander

shows similar data on its web site for its ozone generators,

with air flow rates of 0 to 600 liters per hour. The flow

rate required to reach maximum total ozone production varies

with the unit, but in all cases shown is more than 50 liters

per hour, and for the larger units is more than 300 liters

per hour. I do not know what flow rates all companies use

to set the specifications of mg of O3/hr

that are touted in sales literature, or if those flow rates

used even match the recommendations that they provide to aquarists

who use the devices. Such issues have been noted before in

the literature2

where it can be difficult to compare commercial ozone generators

without knowing the flow rates that were used when making

the calculations.

|

|

Figure 2. The relationship between the air flow

rate and the resulting ozone concentration (black) and

the total ozone produced (red) for a typical corona

discharge ozone generator.

|

Note that even if the commercial ozone generators used by

aquarists produce a fixed amount of ozone per unit of time,

the concentration in the air flowing through them will decrease

as their flow rate increases.

In summary, the considerations with respect to air flow rate

are:

1. Higher flow rates may mean higher total O3

production, maximizing the ozone generator's efficiency.

2. A higher flow rate means a lower concentration of O3

in the air. This reduction can lead to a lower transfer

of ozone into the water (because the equilibrium amount

entering the water depends on the concentration of O3

in the air). Large air volumes may also affect what sort

of contact chamber is required to expose the tank's water

to that air. Most can handle only a certain amount of air

before malfunctioning, or at least decreasing the amount

of water in it or the air's rate of turnover.

3. Higher flow rates may make it more difficult for ordinary

drying tubes to adequately remove the moisture from the

air before it gets to the ozone generator. Higher flow rates

will also necessitate renewing the drying agent more often.

More comprehensive advice will be given at the end of the

article, but my advice with respect to air flow is as follows:

1. Size an air pump so that it is in the range of flow

rates recommended by the ozone generator's manufacturer,

and perhaps also the contact chamber to be used. Perhaps

use an air pump with a variable flow rate so that it can

be adjusted during operation.

2. Use an air pump that can handle back pressure. How important

this aspect is will depend on the nature of the pressure

inside the contact chamber (next section).

3. Once the system is in operation, the air flow and other

parameters can be adjusted to maximize performance. The

aquarium's ORP is one easy, albeit slow, way to gauge performance.

The ozone concentration in the water exiting the contact

chamber, but ahead of the GAC,

can be a good gauge. A chlorine or ozone test kit can be

used to detect ozone and its byproducts in seawater since

these compounds will react with the reagent in a standard

chlorine kit. When using a Hach CN-70 chlorine kit (using

the directions for either free or total chlorine), I found

experimental values ranging from 0.02 to 0.5 ppm "chlorine

equivalents" in different setups that I tried, not

just varying air flow). Since such kits (which are based

on a method called DPD

or DDPD) detect a variety of different highly oxidizing

species (hypobromite, ozone, etc.), it must be remembered

that it is not an indication of just the total free ozone

remaining. Nevertheless, the convention is to report all

of these highly oxodizing species as if they were a single

chemical (unless noted otherwise in a published study).

The units can be chlorine

equivalents or ozone

equivalents, with 1 ppm chlorine equivalent equal to

0.7 ppm ozone equivalents (that value simply being the ratio

of the molecular weight of O3

(48 g/mole) divided by the molecular weight of Cl2

(70.9 g/mole). Note that a test method using indigo

blue (indigo trisulfonate) tests for ozone only, and

not the byproducts, so do not choose that method unless

you only want ozone measurements.

The ORP of the contact chamber effluent can also be a useful

gauge (mine is typically in the upper 600's mV). In all

cases, the higher the ozone or ORP, the more effectively

the ozone is being used (at least when the flow rate of

water through the reaction chamber is approximately constant).

Air Drying

Ozone generators using corona discharge

operate most efficiently when the air entering them is dry.

While the exact relationship between humidity and the ozone

production rate depends on the generator's design, most commercial

ozone generator manufacturers (O3ozone,

Ozone

Solutions and Lenntech,

for example) show graphs of ozone production vs. humidity

that look something like Figure 3. Many aquarists know the

rule of thumb that ozone generation efficiency drops by about

a factor of two between dried and undried air, and Sander

makes a similar claim for its ozone generators on its website.

Specifically, Sander

claims that drying the ambient air with a relative humidity

of 50% to dry air with a dewpoint of -40°C causes a 50%

reduction in the ozone output of one of its line of ozone

generators.

Data such as that in Figure 3 would seem to show that the

maximum potential effect of drying is likely to be somewhat

larger than two-fold if using ambient air, which can have

dewpoints running up to 20°C or even higher, compared

to very dry air (with a dewpoint below -60°C). For convenience

in interpreting Figure 3, the table below shows the relationship

between relative humidity and dewpoint when the air temperature

is 70°F (21.1°C). Obviously, the air must be very

dry to have a dewpoint below -20°C. It is not obvious,

however, whether the sorts of air dryers used by hobbyists

approach or exceed this low dewpoint.

|

|

|

Table

1. The relationship between the dewpoint

and the relative humidity at 70°F (21.1°C).

|

|

Relative

Humidity

|

Dewpoint

(°C)

|

|

90

|

19

|

|

80

|

18

|

|

70

|

15

|

|

60

|

13

|

|

50

|

9

|

|

40

|

6

|

|

30

|

0

|

|

20

|

-8

|

|

6.6

|

-15

|

|

4.2

|

-20

|

|

1.5

|

-30

|

|

0.5

|

-40

|

|

0.16

|

-50

|

|

0.04

|

-60

|

|

0.01

|

-70

|

|

0.002

|

-80

|

|

|

| |

|

Figure 3. The relationship between the

dewpoint (humidity) and the relative amount of

ozone produced in a typical corona discharge ozone

generator.

|

|

|

It is also claimed that higher humidity in the incoming air

can increase the output of nitric acid, but not all researchers

agree on this assertion.2

Some resources3

recommend that the dewpoint be kept very low (~-60°C)

in order to prevent corrosion of the unit itself by nitric

acid's formation inside it. Again, however, it is not obvious

whether the sorts of dryers used by hobbyists approach this

very low dewpoint.

One aquarist reported corals in his aquarium started looking

poorly, and discovered that there was a blue liquid in the

tubing between his ozone generator and a brass fitting. he

had not been using an air dryer, and it was a humid day. That

liquid may well have been nitric acid in water that corroded

the brass fitting to release copper, that then made its way

to the aquarium. A more extensive discussion of the chemistry

behind nitric acid formation is presented in the next section.

In any case, most ozone generator manufacturers suggest that

the air be dried before it enters the generator, and aquarists

have several options for drying the air. Some commercial

devices can dry air rapidly and automatically, although

they are considerably more expensive than other options. These

commercial devices are especially useful in high air flow

applications (many liters per minute).

The simplest dryer is a plastic tube filled with a material

that binds to moisture in the air. The air flows in one end

and out the other, and gets dried while passing through. Red

Sea sells such a device in at least two sizes. Their material

(silica

gel) changes color from blue to pink as it is exhausted,

and it can be regenerated in a standard oven by warming it

up, thereby driving off the absorbed water. Unfortunately,

my device came missing a critical O-ring, and when I resorted

to making it myself, the unit sometimes could not hold adequate

pressure. It also seemed to become depleted faster than I

had hoped. In my system I used the larger size (500 g), but

found that it typically became depleted in two weeks or so.

That result is apparently mirrored by others' experiences,

so anticipate such a discharge period. Nevertheless, the color

changing ability makes depletion apparent. I also found a

surprisingly small effect of using the dryer on ozone in the

effluent from the reaction chamber, and on overall aquarium

ORP. Details of that finding will be discussed next month,

but that result may reflect a lack of effectiveness of the

drying tube, or alternatively, a lack of a large effect of

humidity on the ozone production by the Aquamedic ozone generator

that I used.

Some aquarists use two units in series, so one can be swapped

out for regeneration while the other is still in place. Figure

4 shows the setup used by Jose Dieck, in which he has drying

tubes mounted on a wall with quick disconnects to permit rapid

swapping in and out as necessary. In addition to simplifying

the replacement process, such a setup may drive the dewpoint

lower than a single pass system using the same tubes.

|

Figure 4. The ozone generation setup used by

Jose Dieck, showing two drying tubes used in series.

|

Do-it-yourselfers may be able to buy silica

gel themselves and fashion a drying tube. Other materials

might work, but may entail complications. Damp-Rid,

for example, may actually liquefy in the presence of too much

moisture, and it may also not reduce the humidity enough.

No Dryer

Ozone generators using UV light to generate ozone (e.g.,

Ultralife)

require no drying of the source air. In addition, many aquarists

using corona discharge ozone generators just skip the air

dryer when using ozone, and seem to be happy with the ozone's

usefulness in their setup. The fact that they may be getting

only 50%, 10% or even 2% of the rated output may not be important

to them. If the aquarium's ORP rises enough without a dryer

that an ORP controller is actually "controlling"

it by shutting off the ozone for some portion of the time,

then the ozone production is obviously adequate. Likewise,

if the ORP is such that the aquarist has dialed back the O3

generation setting on the generator to less than maximum,

and is happy with the results, then a dryer would not likely

be especially beneficial.

Water clarity may improve at levels of added ozone far less

than required to raise the ORP to the often mentioned 350-450

mV range. In the end, all that matters is that the aquarist

is satisfied with the water's clarity and with whatever other

expectations he has for its benefits. The undesirable effects

of nitric acid production (slight additions of nitrate, slight

reductions in alkalinity and pH) are likely trivial compared

to the huge additions of nutrients and buffers that many reef

aquaria experience.

Will the inside or the fittings of a corona discharge ozone

generator unit degrade over time due to nitric acid corrosion?

I do not know the answer to that.

In my setup the ORP never rises above 330 mV, and is more

typically 300-330 mV even with the ozone unit that I have

turned to its highest setting, and with an air dryer (all

of which I will detail next month). This result suggests to

me that I am nowhere near overdriving the ozone addition.

For this reason it would seem prudent to continue to use a

dryer, but the actual experimental results that I obtain over

the coming months (where humidity is likely to rise further)

will determine if continued use of the drying tube is warranted

going forward.

My advice to others with regards to air drying is:

1. More ozone may be produced by the ozone generator if

the air is adequately dried first, assuming it is a corona

discharge type. It remains to be established, however, whether

simple commercial air drying units have the desired effect.

2. The ozone generator itself may last longer if the air

is adequately dried (again, assuming it is a corona discharge

type).

3. Assuming that water clarity is the primary or only goal

of using ozone, and not the more difficult to achieve goal

such as disinfection of the water, many aquarists will likely

be satisfied using ozone without an air dryer.

Air Flow Check Valve

An air flow check valve is an inexpensive

and potentially important piece of equipment. It can be used

between the dryer and the ozone generator, or between the

ozone generator and the ozone reaction chamber. Being a high

voltage electrical device, ozone generators do not mix well

with seawater. While many seem able to withstand occasional

water contact (and some even recommend cleaning inside the

air passage with distilled or RO/DI water), deposits of salts

and other materials is likely not desirable. Even if the ozone

generator is located higher than all other pieces of equipment,

some ozone reaction chambers have enough pressure in them

that if the air flow stops, water can back up in the air line

to a considerable extent.

If used between the dryer (or air pump) and the ozone generator,

any check valve is adequate. If air cannot move backward through

it, then in a power failure when the air pump turns off, water

cannot come up the air line tubing into the generator. In

this setup, water can come up the tubing if the air line between

the generator and the check valve somehow comes off.

If used between the ozone generator and the ozone/water reaction

chamber, an ozone resistant check valve is preferable (if

one can be found). In this setup, water cannot reach the ozone

generator as long as the check valve is in place. In the absence

of ozone resistant valves regular check valves can be used

and swapped out frequently as the rubber in them degrades

due to ozone exposure. The materials that are most suited

to surviving ozone exposure are detailed later

in this article.

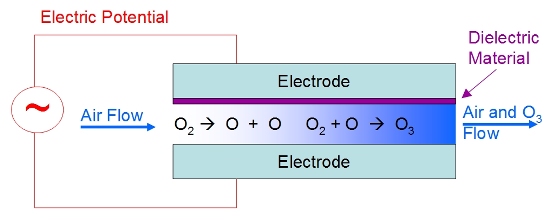

Ozone Generators: Electric Discharge

Theory

Ozone has historically been generated

in a variety of ways for aquarium applications. These include

high energy UV radiation and electrical discharges. Most,

but not all, commercial ozone generators intended for aquarium

use employ electrical discharge. Figure 5 shows a typical

electrical discharge unit. In it, air is passed between two

electrodes. An alternative design is to simply have the air

pass through a glass

tube that is between two electrodes. While any charge

separation across the electrodes can work, an AC (alternating

current) field is often used. The exact nature of the electrical

field varies, and usually falls into one of the following

frequency ranges: low frequency (50 to 100 Hz), medium frequency

(100 to 1,000 Hz) or high frequency (1,000+ Hz). I am not

sure what frequencies are used in each of the commercial brands

commonly employed by aquarists. A thin dielectric material

is coated on one or both electrodes to prevent actual sparking

between the electrodes. That dielectric material can be glass,

mica or other nonconductive materials, but is usually glass.

The electric field between the electrodes is strong enough

to rip apart molecules and is called a corona or corona discharge.

Coronas often emit light, and while that effect cannot be

seen in typical commercial ozone generators, it can be seen

in other applications where the corona is not so enclosed.

|

|

Figure 5. A schematic of the internal workings

of a corona discharge ozone generator.

|

The intense electric field, and the high energy ions within

it, can rip apart all of air's primary components into very

reactive individual atoms or radicals:

N2

à 2N

O2

à 2O

H2O

à

H + OH·

These species can then react among themselves, or with unreacted

components in the air. It is beyond the scope of this article

to detail plasmal chemistry, but the reaction of most interest

to us is:

O

+ O2 à O3

(ozone)

As mentioned above, the air flow through the generator can

impact the amount of ozone produced. With an understanding

of how ozone is produced in such generators, it is easy to

see why. If O3 is produced

between the electrodes, and sits there for a period of time,

the ozone itself can be ripped apart by the intense electric

field and by collisions with high energy electrons and other

species:

O3

à O2

+ O

A higher air flow rate can help to sweep the initially formed

ozone out of the generator before it can be broken apart,

and to replace it with fresh O2 that

is ready to produce more ozone.

Several reaction sequences can result in nitric acid:

O2 + H

à

HO2·

N + O

à

NO·

HO2·

+ NO· à

HNO3 (nitric acid)

and

N + O2

à

NO2·

OH·

+

NO2· à

HNO3 (nitric acid)

The last sequence requires that water be present (to get

to OH·) and it's

apparent how a high water concentration (as indicated by the

humidity or dewpoint) might increase the nitric acid concentration.

These sorts of processes can also explain how high water

concentration in the air (i.e. high humidity or dewpoint temperature)

might decrease ozone production. Instead of reacting with

O2 to produce ozone, for example, an

oxygen atom can react with the breakdown products formed from

water (H and OH·)

to produce other chemicals. Other reactions among these species

also lead to products such as hydrogen peroxide and nitrous

acid, but they are lower in concentration than oxygen.

Ozone Generators: UV Theory

As mentioned above, ozone can also

be generated by intense ultraviolet light. The ozone generators

sold by Ultralife

fall into that category. These devices use a special light

bulb producing short wavelength UV light (often 185 nm). During

UV exposure at this wavelength, O2

molecules in air passing near the bulb absorb the light and

are broken apart:

O2

à 2O

As with electric discharge units, these oxygen atoms can

then combine with O2 to

form ozone:

O

+ O2 à

O3 (ozone)

The manufacturers of these types of units claim that their

advantages are that the air need not be dried, and that fewer

nitrogen-containing byproducts are formed (e.g., nitric acid).

Additionally, their bulb is said to last for two to three

years before needing replacement. Competitors have claimed

that these types of ozone generators lose about 20% of their

rated output after a few hours of operation, and that the

electrical power consumption is much higher for a UV based

system than for corona discharge. The maximum

concentration of ozone that can be obtained in a given

air volume is lower (01 - .1% by weight O3

in air for UV systems compared to 0.5 to 1.7% O3

in air for dried air using corona discharge). Note that the

UV type ozone generators' output often is not adjustable.

Also noteworthy is that these units are distinctly different

from UV sterlizers. Ultraviolet sterilizers use a longer wavelength

of UV light (about 254 nm, typically) and kill organisms by

UV's direct interaction with the tank's water as it passes

by. Molecules such as DNA in the organisms absorb the 254

nm UV and the molecules break apart, killing them. Ultraviolet

light at 254 nm does not produce significant ozone.

Which type of ozone generator is better? I chose a corona

discharge type for my setup, but either method is adequate

for most hobbyists.

Ozone Generators: Practical Information

As a practical matter, ozone generators

are easy for aquarists to use. If their ozone output is adjustable,

the device will have a control dial on it. Such a dial controls

the power applied across its internal electrodes. Otherwise,

there is nothing to set or adjust (unless the ozone generator

comes packaged in a box with a redox controller, which is

discussed below). If they are not adjustable, they may have

nothing more than an electric cord, an air inlet and an air/ozone

outlet.

Ozone generators for aquaria that use a corona discharge

consume very little electricity. Typical aquarium units use

10 watts or less (for 300 mg O3

per hour or less). They usually come with adequate directions

for their use. Ozone generators frequently used by aquarists

in the United States include those made by Sander,

Aqua

Medic, Enaly

and Red

Sea. Units based on UV light (e.g., Ultralife)

typically use more electricity.

Gauging how much ozone is necessary is not trivial, and may

depend strongly on the desired outcome from dosing ozone,

how it is used and the other husbandry practices used in the

aquarium. Clearing up yellowing in the water, for example,

uses far less ozone than is necessary to sterilize the water.

Likewise, a good ozone/water reaction chamber might allow

far less ozone to be used than is required by an inefficient

use in a skimmer. That being said, most guidelines suggest

on the order of 0.3 to 0.5 mg O3/hr/gallon

of aquarium water.

If possible, I would suggest locating the unit above the

water's level where it is being used. All sorts of malfunctions

(power failures, air pump failures, loose air line, etc.)

can send water back up the air line tubing and into the ozone

generator. Such water contact may not immediately ruin a corona

discharge unit, but it will contribute to poor output and

may eventually cause it to quit functioning. I am not sure

what effect contact by liquid water would have on a UV based

ozone generator, but it would not surprise me if it could

shatter the bulb. An air check valve also helps reduce the

likelihood of water contact. I have my Aquamedic ozone generator

attached about 7' off the floor of my basement, where the

treated water is sent into the reaction chamber and ultimately

into the sump that is about 3-6' lower. Nevertheless, I have

accidentally sent water into my ozone generator several times.

In each case, the amount of ozone in the reaction chamber

seems to come back to normal after 24 hours, but this practice

is likely less than desirable.

Check with the manufacturer or the supplied directions before

attempting to clean the inside of an ozone generator. Some

recommend cleaning with pure fresh water and a brush, but

that is not possible with other designs. My Aquamedic unit

is sealed with a membrane of some sort, so poking any solid

object into the fittings will damage it.

Ozone Reaction Chamber: Skimmers

The ozone reaction chamber is the

heart of the system. It is the place where air, laden with

ozone, and water from the aquarium are mixed together. In

the first article in this series I detailed the chemistry

and biochemistry that occur in the reaction chamber. I also

discussed issues relating to contact time and ozone concentrations

with respect to some of ozone's potential effects (such as

disinfection).

A variety of different systems can be used as contact chambers,

and most reef aquarists choose to use skimmers. They use either

their main skimmer or a smaller, inexpensive one that can

run at a lower flow rate and potentially be sacrificed if

the ozone degrades the plastic to the point where it no longer

is reliable. Despite their widespread use with ozone, skimmers

are not usually an optimal way to employ ozone for several

reasons:

1. Their water and air flow rates, and even their engineering

design itself, are optimized for skimming, not for ozone

injection and reaction. The longer the ozonated water has

to react, the more oxidation of organic molecules can take

place. This is not a design criterion with skimmers, where

the air/water contact time is maximized, but the water alone

is not held for any purpose. If the water's flow rate is

too high, and hence its turnover rate too high, the concentration

of ozone in the water, and the contact time for it to react

with organic materials, may be less than optimal.

2. Both the air and water exiting the skimmer should optimally

be passed over activated carbon to reduce the highly oxidizing

and toxic species being sent into the aquarium and into

the aquarists' home air. Many skimmers are not set up to

efficiently pass the air over carbon, and high water flow

rates can make it difficult to achieve adequate contact

with activated carbon.

3. Many skimmers are not designed using materials suitable

for prolonged ozone exposure.

Nevertheless, the majority of reef aquarists who use ozone

do so with a skimmer. Whether it is optimal or not, they have

decided it meets their needs. How ozone is used with a skimmer

depends critically on the nature of the skimmer, and too many

different designs exist to provide many useful details. However,

some suggestions for using ozone this way are:

1. Select a skimmer that allows a substantial volume of

water to be contained within it, so that the ozonated water

is not immediately swept away and passed over the GAC (where

the ozonation reactions largely end).

2. Select one that lets you collect the air and pass it

over GAC. A Sea Clone, for example, would be a poor choice

in this regard as the air and water exit it from a fairly

large opening. The ETS skimmer that I use is also a poor

choice, as the air comes out of a tube that is also the

skimmate outlet. It can, however, be used with a special

skimmate collector (described below).

Jose Dieck has modified a commercial skimmate collector (PS-MQWC2)

that works in conjunction with his skimmer. He made a new

cap, extended the length of the neck between the top flange

and the carbon container and re-tapped the flange to accept

a larger ¾" fitting for the drain. Originally,

the carbon was intended to remove the skimmate's smell, but

it can also work to reduce ozone. It allows the liquid skimmate

to be collected and diverts the ozone-laden air through an

activated carbon filter (Figure 6). It requires the skimmate

to be drained by gravity from the skimmer cup to the collector

chamber without releasing any of the air. The air/skimmate

mixture enters at the top, the liquid settles to the bottom

and the ozone laden air comes out through the middle of the

top. It passes over carbon, thereby losing its ozone. It can

also be vented outside, as desired.

|

Figure 6. A modified skimmate collection container

that is used by Jose Dieck to reduce airborne ozone

release.

|

Ozone Reaction Chamber: Commercial

Reactors and DIY

Several commercial ozone reactors

are available, which range from poor to what is likely quite

effective (albeit expensive). I have used the Coralife Ozone

Reactor (Figure 7), and won't use it again. In my opinion

it is not a well-designed product. I'll provide more commentary

on it next month.

|

Figure 7. The Coralife ozone reactor with attached

tubing for water and air flow.

|

Marine Technical Concepts (MTC) also makes an ozone reactor,

the PRO240D.

It consists of a 6" diameter acrylic tube that is 27"

tall. Inside the water is dripped through a plate and then

onto a high surface area plastic material. The air/ozone mixture

is injected above the plate allowing them to mix. This type

of reactor is typically pressurized to several PSI, driving

the ozone into the water. I've not used it, but I am confident

that this reactor would be a good choice.

Those who want an ozone reactor but who are not able to spend

several hundred dollars might use the PRO240D

or these linked

plans as guides for DIY (do-it-yourself) systems.

Ozone Reaction Chamber: Tubing

Reactor

After messing with the Coralife Ozone

reactor and finding it unsatisfactory, and doing some tests

where I simply sent the ozone into my skimmer (making my basement

stink of ozone), I decided to set up a very simple "reactor"

myself (Figure 8). I have two Iwaki 30 RLXT pumps in series

that I have used for years as my main return pumps. I created

a "T" off of their output to send water to my two

main tanks.

|

Figure 8. The 100' coil of HDPE tubing that I

used as a simple ozone reactor.

|

Using another "T" I added a ¾" venturi,

and to it I attached a 100' coil of ¾" HDPE (high

density polyethylene) tubing that I bought from Cole Parmer

for about $60 (including shipping). The reactor simply consists

of the air/ozone mixture pumped into the venturi, and then

the water/air/ozone mixture circulates through this coil (about

13 individual coils) for about 45 seconds (when the water's

flow rate is about 90 gallons per hour). It contains a little

over two gallons of air and water at a time. This allows for

a long contact time with a significant amount of water, and

a fair amount of pressure exists both from gravity and from

the back pressure of 100' of coiled tubing. In fact, the tubing

coil had to be laid horizontally. Hanging it vertically created

too much back pressure to get any significant water flow through

it.

While the mixing efficiency is apparently not especially

good inside the tubing, it is adequate to raise the ORP to

> 680 mV and the ozone concentration in the water (as measured

with a chlorine kit at the outflow) to 0.1 ppm chlorine equivalent.

In this setup, the venturi simply acts as an inlet for the

pumped air because the flow rate is too low to actually get

any suction by venturi action.

Most important to me, the end of the tubing where the air

and water exit is easily passed through a column of GAC to

remove residual ozone and ozone by-products. In normal operation

I smell no ozone in the basement room where the operation

takes place. There is also no place for any detritus to collect

in this system, except on the activated carbon itself. The

GAC column is detailed later in this article.

Ozone Reaction Chamber: Suitable

Materials

For those designing and building ozone

systems, using the proper materials is an important factor.

Some plastics and rubbers rapidly become brittle and break

after prolonged exposure to ozone. A number of different online

sites have compatibility guides; Cole

Parmer, for example. The information in Table 1 was taken

from their information on "materials." They also

have a tubing

selection guide (shown in Table 2).

Clearly, some materials that aquarists might use, such as

nylon, are not the best choice. Aquarium supply shops sell

ozone-resistant tubing, which is a good choice

for use between the ozone generator and the reaction chamber.

|

Table

1. Material's Compatibility with Ozone

|

| Material |

Rating

|

| ABS

plastic |

Good

|

| Acetal

(Delrin®) |

Fair

|

| Buna-N

(Nitrile) |

Severe

Effect

|

| Butyl |

Excellent

|

| CPVC |

Excellent

|

| Durachlor-51 |

Excellent

|

| Durlon

9000 |

Excellent

|

| EPDM |

Excellent

up to 100°F

|

| EPR |

Excellent

|

| Ethylene-Propylene |

Excellent

|

| Flexelene |

Excellent

|

| Fluorosilicone |

Excellent

|

| Glass |

Excellent

|

| HDPE |

Excellent

|

| Hypalon® |

Excellent

|

| Hytrel® |

Fair

|

| Kalrez |

Excellent

up to 100°F

|

| Kel-F®

(PCTFE) |

Excellent

|

| LDPE |

Good

|

| Natural

rubber |

Severe

Effect

|

| Neoprene |

Fair

|

| Nylon |

Severe

Effect

|

| PEEK |

Excellent

|

| Polyacrylate |

Good

|

| Polyamide

(PA) |

Fair

to Severe Effect

|

| Polycarbonate |

Excellent

|

| Polypropylene |

Fair

|

| Polysulfide |

Good

|

| Polyurethane,

millable |

Excellent

|

| PTFE

(Teflon®) |

Excellent

|

| PVC |

Good

|

| PVDF

(Kynar®) |

Excellent

|

| Santoprene |

Excellent

|

| Silicone |

Excellent

|

| Stainless

steel - 304 |

Good/Excellent

|

| Stainless

steel - 316 |

Excellent

|

| Teflon |

Excellent

|

| Titanium |

Excellent

|

| Tygon® |

Good

|

| Vamac |

Excellent

|

| Viton® |

Excellent

|

|

|

|

Table

2. Tubing's Compatibility with Ozone

|

| Tubing

Type |

Ozone

Resistance

|

| Bev-A-Line®

IV |

D

|

| Bev-A-Line®

V |

D

|

| Bev-A-Line®

XX |

C

|

| Chemfluor®

367 |

A

|

| ETFE |

A

|

| FEP |

A

|

| Gum

rubber |

C

|

| Kynar® |

A

|

| MFA |

A

|

| Norprene® |

A

|

| Norprene®

food-grade |

A

|

| Norprene®

pressure |

A

|

| Nylon |

C

|

| PEEK |

A

|

| PFA |

A

|

| PFA-450

high-purity |

A

|

| PharMed® |

A

|

| Polyethylene |

B

|

| Polyethylene,

FEP-lined |

A

|

| Polyimide |

A

|

| Polypropylene |

C

|

| Polyurethane

(clear, aqua-tint) |

A

|

| Polyurethane

(red, green, blue, black) |

A

|

| PTFE |

A

|

| PTFE

color-coded |

A

|

| PVC |

A

|

| PVC

Bubble® |

B

|

| PVC

food-grade |

A

|

| PVC

reinforced |

B

|

| PVC

wire-reinforced |

B

|

| Silicone,

peroxide-cured |

A

|

| Silicone,

platinum-cured |

A

|

| Silicone

reinforced peroxide |

A

|

| Stainless

steel, 316 |

A

|

| Tygon®,

FEP-lined |

B

|

| Tygon®

fuel/lubricant |

A

|

| Tygon®

food/beverage |

B

|

| Tygon®

high-purity |

B

|

| Tygon®

high-purity reinforced |

B

|

| Tygon®

lab; vacuum |

B

|

| Tygon®

sanitary silicone pres. |

A

|

| Tygon®

silicone |

B

|

| Tygon®,ultra

chemical-resistant |

B

|

| Tygothane®

pressure |

A

|

| Vinyl |

C

|

| Viton® |

A

|

|

A—No

damage after 30 days of constant exposure.

B—Little or no damage after 30 days of

constant exposure.

C—Some effect after 7 days of constant

exposure. Effects may include: cracking, crazing,

loss of strength, discoloration, softening, or

swelling. Softening and swelling are reversible

in some cases.

D—Not recommended for continuous use. Immediate

damage may occur.

|

|

Ozone's Safety to Humans: Background

Ozone in the air can be a significant

health

hazard to humans. A recent EPA study (to be published

in April of 2006 in Environmental

Health Perspectives) shows that ozone can cause premature

death at prolonged exposure levels as low as 0.08 ppm. That

level is considerably lower than had been previously believed.

Older studies had suggested that a level of 0.2 ppm was not

a significant health risk. It is beyond the scope of the article

to detail ozone's various health effects, but it should be

apparent that if ozone can be used to oxidize and break down

organic materials, then ozone exposure to humans, which are

made up of organic tissue, is undesirable.

Since most aquarists do not have ozone detection meters (see

below), how should they determine if they are potentially

being exposed to undesirably high levels? Aside from not using

ozone, which might be a reasonable choice for many aquarists

for many reasons, including health, I would recommend the

sniff test. It appears that most people can detect ozone in

the air by smell at levels somewhat below 0.08 ppm. So, if

you can smell ozone, it may or may not be at dangerous levels.

It is quite possible, however, to use ozone in a manner where

it cannot be smelled, assuming that the equipment and procedures

are adequate, including passing the post-reactor air over

a suitable amount of GAC (discussed in the next section).

My advice, then, is that if you choose to use ozone, you do

so in a way in which you cannot detect its odor. Is that a

guarantee that you will suffer no harmful effects? No. Some

people have a much poorer sense of smell than others. And

future studies may show harmful effects even at levels below

the threshold of detection by the human nose. But if I were

using ozone, and I could smell it, I would take affirmative

action to reduce the escape of the ozone gas.

For those who are interested, many brands of ozone meters

are suitable for determining if undesirable levels of ozone

are in the air. They are, unfortunately, fairly expensive.

The EW-86316-20

Ozone Meter from Cole Parmer, for example, sells for $350

and shows levels from 0.02-0.14 ppm. Some test kits also involve

exposing a sensitized card to the air. Smart and Final ad

is a unique sale for businesses, too.These are not expensive,

and for aquarists concerned about ozone safety, they may be

a good way to ascertain whether a particular setup poses any

risk. Kits can be obtained from many outlets, including:

http://www.iaacm.org/freeozonetest.html

http://www.alerg.com/page/A/PROD/TK/AVC2000

http://www.indoorairtest.com/ozone.asp

For reference purposes, the summary of ozone health effects

that was presented in the first article in this series is

reproduced below for convenience.

Ozone's Effects in the Lower Atmosphere:

0.003 to 0.010 ppm

Lowest levels detectable by the average person (by

odor).

0.08 ppm

Latest EPA study (to

publish in April 2006) reports significantly

increased risk of premature death in humans. Each

0.01 ppm increase results in a 0.3 percent increase

in early mortality.

0.001 to 0.125 ppm

Ozone concentration in natural air.

0.1 ppm

The typical maximum allowable continuous ozone concentration

in industrial work areas and public and private

spaces.

0.15 to 0.51 ppm

The typical peak concentration in American cities.

0.2 ppm

Prolonged exposure of humans under typical work

conditions produced no apparent effects.

0.3 ppm

The threshold level for nasal and throat irritation.

Some species of plant life show damage.

0.5 ppm

The level at which Los Angeles, California declares

its Smog Alert No. 1; can cause nausea and headaches.

1 to 2 ppm

The level at which Los Angeles, California declares

its Smog Alerts Nos. 2 (1.00 ppm) and 3 (1.50 ppm).

Symptoms: headache, pain in the chest and dryness

of the respiratory tract.

1.4 to 5.6 ppm

Causes severe damage to plants.

5 to 25 ppm

Lethal to animals in several hours.

25+ ppm

Likely lethal to humans in one hour.

|

Ozone's Safety to Humans: GAC

for the Air Effluent

In order to reduce the level of ozone

in the air passing out of an ozone reaction chamber or skimmer,

it is best to pass the air over a suitable amount of activated

carbon (or perhaps to divert it outside of the home, as some

aquarists do now). As ozone binds to activated carbon (shown

as C*), it first dissociates on the carbon's surface into

bound O and O2:

O3 + C* à

O2 + CO*

The O2 is released into the air stream.

Some of the oxidized activated carbon remains, but most breaks

down to produce more O2 that is released:

2CO* à

2C* + O2

While the types of activated carbon most suited for this

gas phase application may be different from those suited for

treating water, it turns out that those used by aquarists

can be effective. Passing the effluent air through a few inches

of packed Marineland Black Diamond brand activated carbon

mostly removed the odor from the room where I performed my

test experiments. The only way to detect the odor by nose

was to sniff directly at the top of the GAC column. In the

absence of the GAC, the ozone released was sufficient to make

the entire basement smell strongly of ozone, and that was

true whether I ran the ozone through the Coralife Ozone Reactor,

my ETS 800 Gemini skimmer or my tubing reactor (additional

measurements using each setup will be detailed next month).

Unfortunately, it is not always easy to achieve such an ozone

reduction due to the way many skimmers release air. In my

opinion, the lack of a suitable way to treat the air effluent

with GAC is a substantial drawback of any reactor or skimmer

for which it is an issue. Some commercial carbon filters are

designed for just this purpose. The CAF-12

Carbon Air Filter made by Marine Technical Concepts, for

example, fits the requirements for this application.

I designed my own combination filter to treat both the air

and water effluent from the ozone reactors that I use (Figure

9). It consists of a 4" diameter PVC pipe cut about 2'

long. On one end I attached a 4" to 3" reducing

fitting, and stuck in a 4" circle of plastic mesh (sold

to keep leaves out of house roof gutters). This mesh sat at

the interface between the 4" PVC and the reducing fitting.

On top of that I placed a large bag of GAC, and on top of

the bag I filled the remainder of the pipe with loose GAC

(Marineland Black Diamond).

|

Figure 9. The homemade activated carbon column

that I used to treat both air and water to reduce ozone

and its byproducts. It is 18" tall and made of

4" PVC pipe.

|

This column of GAC is held up by a string attached to the

upper end of the pipe. The string's other end is attached

to a ceiling joist. The bottom of the column (the reducing

fitting) sits on a 3.5" hole cut into the plastic trashcan

lid that sits on top of my sump. The PVC is largely resting

on the sump's cover, and the string just keeps it upright.

Depending on the ozone reaction chamber being used, either

both the air and water outlets (for the Coralife Ozone Reactor),

or the one combined outlet (for my tubing reactor), is stuck

into the column. Specifically, the end of the tubing where

the water and air exit is stuck about 3" below the top

of the GAC, with another foot or more of GAC below it. That

water passes over this foot, and the air likely comes out

the top of the GAC column (although some may also exit the

bottom).

When this GAC column is connected properly, I cannot smell

any ozone in the room, while removing the tubing from the

GAC column rapidly fills the whole basement with ozone that

is easily detected by smell. It isn't pretty, but it is cheap

and works fine!

The skimmate collection container modified by Jose Dieck

that is described in an earlier section (Ozone

Reaction Chamber: Skimmers) is a somewhat more elegant

solution to the need to pass the air coming off of a skimmer

over GAC.

Ozone Safety to the Aquarium:

GAC for the Water Effluent

In order to reduce the level of ozone

and its toxic byproducts

(bromate, hypobromous acid, etc.) in the water passing out

of an ozone reaction chamber or skimmer, it is best to pass

the water over a suitable amount of activated carbon. The

first

article in this series discussed the chemistry behind

activated carbon's catalytic breakdown of ozone and its byproducts,

producing oxygen. This process can be monitored using a chlorine

test, such as the Hach model CN-70,

or one that works similarly but that reports results as ozone

(e.g., the Hach model OZ-2).

The GAC column through which I pass such water (Figure 9)

substantially reduced the reported residual OPO.

Depending on the flow rate and other variables, the drop was

from 0.1 ppm to 0.04 ppm chlorine equivalents or from 0.05

ppm to less than 0.02 ppm chlorine equivalents (the lower

limit of detection). Such GAC treatment does not seem to appreciably

lower ORP, so it is not a good way to gauge the GAC's efficacy.

This application of GAC is, I believe, substantially more

demanding than when merely treating water to remove organics.

In the latter application, if some water passes by the GAC

without interacting with it, it is not a problem; it just

reduces the treatment's effectiveness, but the organics might

be caught the next time the water passes through the GAC.

Or, on the pass after that… and on and on. It is not

a situation where one needs to remove all of something in

a single pass. The OPOs resulting from ozone's reaction with

seawater, however, are not so benign. It is far better to

get them out in the first pass through the GAC. Whatever OPO

gets to the main tank will likely react there. If it reacts

with soluble organics, or with particulate organic material,

that's not problem; it probably is even desirable. But those

reactive species that come into contact with organisms will

be more problematic, as detailed in the first

article.

Ozone's Safety to the Aquarium:

ORP Monitor and Control

Ozone is a powerful oxidizer, and

aquarists need to ensure that they are not adding too much

to their aquaria. There are true stories of aquarists who

have caused tank disasters by adding too much ozone (including,

for example, the death

of three sharks at the Devon Aquarium in 2001 when a computer

failure allowed delivery of too much ozone). Besides properly

sizing the necessary components (ozone generator, GAC treatment,

etc.), there is one relatively simple way to ensure that the

tank is not being overdosed, and that is by monitoring ORP

(the oxidation reduction potential).

I covered ORP extensively in a prior article (ORP

and the Reef Aquarium), including what it really means

and how to measure it. I also discussed ozone's chemical impact

on ORP in the first

article in this series, so I will not dwell on any of

these aspects here. ORP is measured with a simple meter and

electrode combination, just as pH is. Unfortunately, that

is where the analogy to pH ends. The theory behind ORP is

complex, and it is not clear what chemicals in the water an

ORP electrode actually measures. The electrode can also take

hours to days to equilibrate with seawater, as various organic

and inorganic materials bind to it or are released, so its

response to changes may not be fast.

In addition to simple ORP meters such as the Pinpoint brand

shown in Figure 10, many aquarists use ORP controllers (Figure

11). These devices are very useful in that they can shut off

the power to an ozone generator (and to any other desired

devices) if the ORP rises too high. All an aquarist needs

to do is tell the device what the upper ORP limit should be,

and it is ready to go. Some companies (e.g., Red Sea) sell

ozone generators that incorporate an ORP meter or controller.

These may be convenient or less expensive, but they do not

incorporate any sort of inherent advantage.

|

Figures 10 & 11. The Pinpoint brand of ORP

monitor (left) and ORP controller (right) sold by American

Marine.

|

In dosing ozone to a reef aquarium, the more ozone that

is added to the system, the higher the ORP will rise. I do

not agree with assertions that some aquarists have made that

higher ORP means cleaner or "better" water. If ORP

is going to be used as a guide to prevent overdosing of ozone,

however, then some commentary is needed on ORP's target levels.

Without using ozone, reef aquaria vary widely in their ORP

values. Some aquarists report values in the upper 300's of

mV, while a few even claim over 400 mV. My reef system's ORP

runs in the middle to upper 200 mV without ozone. Some claim

even lower values. Part of these ranges may relate to complications

in calibrating ORP measurements and equilibrating ORP electrodes

(a process that can take days), and part to the fact that

ORP varies with pH, but much of it likely relates to real

aspects of husbandry that change the base ORP that an aquarium

attains.

Before going on to discuss ORP and ozone, let me relate one

issue that may impact how strongly aquarists should rely on

the accuracy of ORP. As mentioned above, ORP is not a simple

equilibrium measurement. The probe itself may have a memory

of what it has previously been exposed to, and that may impact

readings, EVEN IF it seems to be properly calibrated. That

memory may relate to organic and inorganic materials attached

to the platinum surface itself. For example, if I calibrate

my ORP probe (in Pinpoint 400 mV fluid), let it equilibrate

in my tank for many days and then put it back into a new batch

of the same ORP calibration fluid, it reads the value it is

supposed to in the calibration fluid. But after returning

it to the tank's water, the tank's ORP reads 25-30 mV higher

than before the probe was put into the calibration fluid,

and that boost lasts for days. Likewise, putting the ORP electrode

into very high ORP solutions (the ozone reactor's effluent,

for example) seems to impact the electrode in the opposite

direction, dropping the tank's observed ORP by about 25 mV

when measured more than a day later (and much more when measured

right away). The take-home message is that aquarists should

not interpret small, absolute ORP changes as meaning anything

in particular, and they may, in fact, simply reflect changes

happening to the ORP probe itself, and not changes actually

occurring in the water.

Upon initiating ozone use, some aquarists, like me, see only

a small rise in ORP even at recommended levels of ozone. My

ORP doesn't rise above 330 mV, for example, and some aquarists'

tanks are still in the 200 mV range even after initiating

ozone. Others, presumably those who start with a high ORP

value, although that may not be the only factor, easily drive

their tank's ORP too high if it is not controlled.

So with all that background discussion behind us, here are

my recommendations for ORP monitoring and ozone control in

reef aquaria using a properly sized ozone generator that appears

to be working, and a properly calibrated ORP meter:

1. If the ORP never seems to rise above 375 mV after initiating

ozone, do not worry about controlling the ozone or the ORP.

Just let it run full out. Also, do not worry about needing

a larger generator, assuming it has driven up the ORP by

at least 25 mV above where it was before adding ozone. It

is likely accomplishing the necessary tasks (such as making

the water clearer). Only if some other aspect of ozone use

is unsatisfying (e.g., lack of water clarity) would I look

for other options such as a larger ozone generator or a

better contact chamber.

2. If the ORP starts above 375 mV, or rises there during

ozone use, using an ORP controller would be valuable to

prevent the ORP from rising too high. Use the controller

to shut off the ozone when the ORP rises too high. Another

option would be to shut off the air flow to save the dryer's

media, but be sure that water cannot flow back into the

ozone generator if the air stops. I would set the ORP target

somewhat above the baseline ORP in the absence of ozone

- at least 350 mV, maybe 400 mV, but never above 450 mV.

Summary

The use of ozone in reef aquaria has

advantages and disadvantages. Chief among the advantages is

the improved clarity of the water. Unfortunately, a significant

concern is the toxicity of ozone and its byproducts to both

humans and reef aquarium inhabitants. The proper use of suitable

equipment, however, can mitigate this risk to a substantial

degree. For those choosing to use ozone, my recommendations

are:

1. Size an air pump appropriate to the ozone generator

and the contact chamber being used. An air pump with a variable

flow rate can be useful. Use an air pump that can handle

back pressure if the contact chamber will be pressurized.

2. Potentially use an air dryer to increase the ozone output,

decrease the nitric acid output and prolong the generator's

lifetime. If using a UV bulb ozone generator, an air dryer

is not necessary.

3. Use a generator sized appropriately for your system,

on the order of 0.3 to 0.5 mg O3/hour

per gallon of aquarium water. While an inordinately large

generator may not cost much more, it can risk overdosing

the aquarium. As with many reef additives, using more than

recommended is rarely better.

4. Many types of commercial or DIY air/water contact chambers

can be used. Optimal systems will have a significant contact

time between the ozonated air and the aquarium's water,

will allow the ozonated water to react for a substantial

period, and may be under significant pressure. Skimmers

can be used, but are far from optimal.

5. For the safety of people in the vicinity of the aquarium,

be sure to pass the effluent air over an adequate amount

of activated carbon to preclude any ozone smell. A test

kit or meter for airborne ozone detection may help ease

aquarists' concerns.

6. For the aquarium inhabitants' safety, pass the ozonated

water over activated carbon to reduce the concentration

of toxic ozone and ozone byproducts in the water.

7. Monitor the ORP when using ozone. If it rises above

375 mV, and it may well not, be sure to carefully control

it so that it does not rise undesirably high (above 450

mV).

8. Once the system is in full operation, the air flow,

water flow, ozone generator setting, GAC treatment and other

parameters should be adjusted to maximize its performance.

ORP can be used to gauge the addition of ozone. A chlorine

test kit can be used to gauge the removal of ozone and ozone

byproducts from the treated water.

For those interested in additional technical details of ozone

generation and use, Stephen Spotte has extensive discussions

in one of his early books, "Seawater Aquariums: The Captive

Environment" from 1979. Although a bit dated, and not

oriented to reefkeeping or to making water clearer, it does

provide a scientific analysis of many ozone generation and

usage issues. I recently bought a used copy from Amazon

for $6. Those designing ozone reaction chambers and related

devices (skimmers, etc.) may be interested in "Aquatic

Systems Engineering: Devices and How They Function" by

Pedro

Ramon Escobal.

Next month my article will describe in detail what effects

ozone had on my aquarium. In the meantime,

Happy Reefing!

|