|

|

Lengthen Weir Gaps, With Professional Resultsby Erik Silver (AgentSPS)

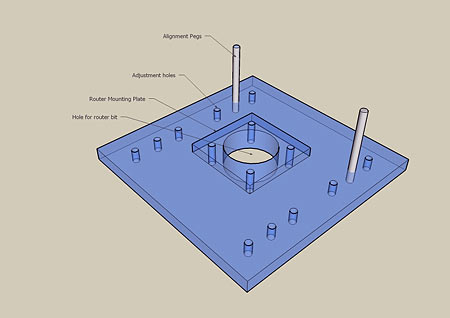

In my build thread, I discussed how the water level runs very high, only about 1/2" from the top of my tank. A surge of current or fish swimming too close to the surface was all it took to spill water over the edge. I racked my brains trying to come up with some way to make the slits in the overflow longer. Below is one of my designs for a jig to retrofit the overflow.

The only thing I remember from Computer Science 101 was that the simplest coding to achieve the desired result was the most elegant. The above design, while it would probably do the trick, was way too complicated to build and probably too bulky for such tight conditions. From an Idea to a RealityI re-thought the whole project. Essentially, all I needed to do was keep a cutting tool perfectly straight, aligned with the existing slits, and make sure it cut down to the same depth on all the slits. This is the final result:

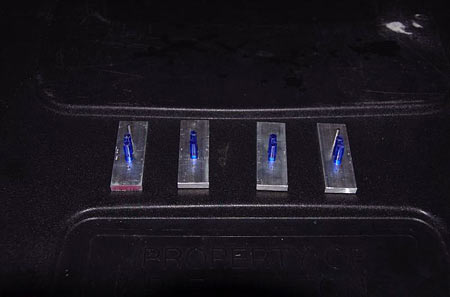

Creating Individual JigsHow did I do it?? The original design was out of acrylic as it is the easiest material for me to work with. The stupid oversight is that the Dremel spins at thousands of revolutions per minute and ended up melting the jig half way through the first slit. The only other easily workable material was aluminum. The hardest part of making the jig is making sure all the holes are on the same center line. If they are not, then you will end up with angled slits. I mounted a piece of acrylic on my drill press table to ensure all the holes came out in a perfectly straight line. There are four holes to be drilled. One is for the Dremel bit to fit through (1/8"). Two are to accommodate 1/4" dowels that slip into the existing overflow slits and act as the guides. The final top hole holds a pin which ensures all the slits are cut to the same depth. My overflow slits are closed at the top. Some tanks have slits that are open and a different design for the stop will be needed. Here are some more photos so you get the idea:

I built four because I found that the tough steel shaft of the Dremel cutting head wears away the aluminum and widens the hole. This creates too much wiggle room for the cutter end, which will result in messy slits. You can grind about 5-7 slits with each jig. If you made it from available steel, it would probably last a lot longer. I used what I had access to.

Here is what it looks like when assembled and hooked up to the Dremel (rotary tool):

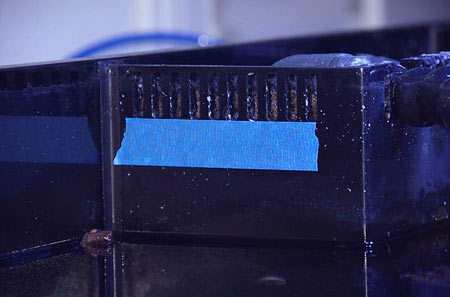

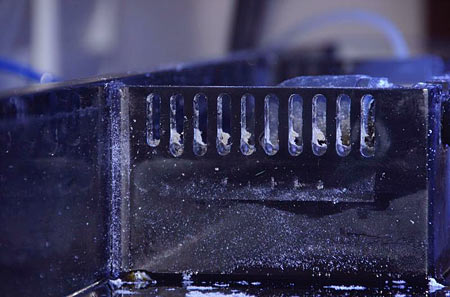

An Idea RealizedImages of the overflow slit, prior to the modifications:

Overflow slit lengthening in progress, about halfway done and time for a fresh jig:

Before I finished, I left the slit on the left untouched for comparison in this picture:

After lowering about half of the total slits by 1/4", I achieved close to 1/4" drop in water level. I only completed the left and right sides of the overflow. I was hoping to avoid doing the ones facing the front as the tank is too wide and too long to conveniently reach that area. The only working plan I've considered is to put some 3/4" plywood over the top of the tank and climb up! Nonetheless, I think I need the water level another 1/4" lower to satiate my OCD. Questions AnsweredHow long did it take to lengthen each slit specifically? I would say each slit took about 2-3 minutes. The Dremel has very little, if any, torque which means the bit would bind with the acrylic often. I also did not want to linger as I feared the bit would create too much heat and melt the acrylic. What is the straight metal pin for (opposite end from the Dremel bit)? This is the stop. The stop ensures all slits are drilled to the exact same depth. For open-toothed overflows, the pin will not work, but there are other options. A horizontal bar instead of a stop pin is an option. How many Dremel bits did you need? I used just one. These are hardened steel coated in tin. It is very sharp and very durable. One key thing is that my slits are 1/4 wide. Dremel brand does not make a cone cutting bit that is 1/4". I believe they use metric. I had to pick up a 1/4" cone cutting bit at my local woodshop (Woodcraft). What is the blue stuff made of, and how was it secured? The blue stuff is just 1/4" diameter round acrylic rod. You can purchase this at Tap Plastics. Metal or wood 1/4" dowel could work too. I just happened to have the rod on hand. If you have any questions or comments about this article, please post in the Notes From The Trenches forum on Reef Central. |

|

|

|

|