|

The use of "TDS" (total dissolved

solids) meters for analyzing the purity of fresh water has

become widespread in recent years. Many aquarists use them

to determine if tap water purification systems such as reverse

osmosis (RO) or reverse osmosis/deionization (RO/DI) are working

properly, or if deionizing resins need to be replaced.

The use of such devices, however, is not

without complications. Contrary to what the name might imply,

for example, these devices do not measure all dissolved solids.

There are also many different units of measure used with TDS

meters. While all are referred to as ppm (parts per million),

they are still different, just as degrees Celsius are different

than degrees Fahrenheit.

This article describes how these meters

work, what they detect and do not detect, and what the units

mean. It also gives some tips on how to best use them.

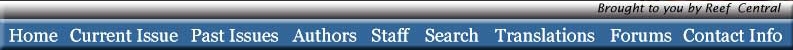

How a TDS Meter Works

TDS meters are, in reality, conductivity

meters. They work by applying a voltage between two or more

electrodes. Positively charged ions (e.g., sodium, Na+;

calcium, Ca++; magnesium,

Mg++; hydrogen ion, H+;

etc.) will move toward the negatively charged electrode, and

negatively charged ions (e.g., chloride, Cl-;

sulfate, SO4--;

bicarbonate, HCO3-;

etc.) will move toward the positively charged electrode (Figure

1). Because these ions are charged and moving, they constitute

an electrical current. The meter then monitors how much current

is passing between the electrodes as a gauge of how many ions

are in solution. A detailed article from a high-end meter

manufacturer on the theory of conductivity measurement can

be found here.

|

Figure 1. Schematic of a conductivity electrode, showing

negatively-charged anions (blue) moving

toward the positively charged electrode, positively-charged

cations (red) moving toward the

negatively charged electrode, and neutral molecules (yellow)

not moving at all.

What Does a TDS Meter Actually Detect?

Since TDS meters are often used to test

water "purity," it is important to understand what

they do not detect. As conductivity meters in disguise, TDS

meters will only detect mobile charged ions. They will not

detect any neutral (uncharged) compounds. Such compounds include

sugar, alcohol, many organics (including many pesticides and

their residues), and unionized forms of silica, ammonia, and

carbon dioxide. These meters also do not detect macroscopic

particulates, as those are too large to move in the electric

fields applied. So if you see "rusty" looking water

from iron oxide particulates, that won't be measured. Neither

will anything else that makes the water look cloudy. Bacteria

and viruses also won't be detected.

Consequently, the term "total dissolved

solids" is really quite a misnomer. "Total charged

ions" is likely a much better term for what it measures.

Fortunately, a measurement of total charged ions is good enough

for many aquarium purposes.

In addition to how many ions are present,

the measured conductivity of a solution is also a function

of what ions are actually present. Table 1 shows the relative

conductivity that is provided when equal numbers of different

ions are present in water. There are differences between the

conductivity of the different ions, and this fact becomes

important in the discussion of the units that are used for

conductivity in subsequent sections.

Ions with higher charges tend to have higher

conductivity because they not only carry more charge but they

respond more strongly to an electric field. Good examples

of this are sulfate (SO4--)

and calcium (Ca++), which

have higher conductivities than sodium (Na+)

or chloride (Cl-). Another

effect is that larger ions tend to have more "drag"

as they move through the water, and thus have lower conductivity.

In such comparisons one needs to take into account the tightly

bound water molecules that get dragged along as well, so one

cannot simply look at molecular weights or ionic radii. This

drag due to the size of the hydrated ion is, for example,

why lithium (Li+) is so

much less conductive than sodium, which in turn is less conductive

than potassium (K+).

|

Table

1. Relative conductivity of various ions.

|

|

Cations:

|

Relative

Conductivity:

|

Anions:

|

Relative

Conductivity:

|

|

H+

|

7.0

|

OH-

|

4.0

|

|

Li+

|

0.8

|

Cl-

|

1.5

|

|

Na+

|

1.0

|

Br-

|

1.6

|

|

K+

|

1.5

|

I-

|

1.5

|

|

Mg++

|

2.1

|

NO3-

|

1.4

|

|

Ca++

|

2.4

|

acetate

|

0.8

|

|

Zn++

|

2.1

|

SO4--

|

3.2

|

"Can I Just Use a Multimeter to Measure Conductivity?"

No. Several factors make it impossible

to accurately measure conductivity with a standard multimeter.

The size and shape of the electrodes are significant, but

more important is what happens at those electrodes. If a DC

current is applied to seawater, numerous reactions take place

when the ions hit the electrodes. Some ions will plate out

on the electrodes, some may bubble off as gases, and the electrodes

themselves may dissolve. These and other effects all serve

to change the nature of the solution at the electrode, impacting

the measured conductivity.

So how do conductivity probes get around

this problem? They use an AC current rather than DC. Using

fields that oscillate very rapidly, there is no overall movement

of ions toward one electrode or the other. The ions move one

way for a tiny fraction of a second, and then back the other

direction for the second half of the cycle. Overall, the solution

and electrodes stay unchanged and the conductivity is accurately

measured. Modern conductivity meters use complex AC waveforms

to minimize additional complications such as capacitance,

which can interfere with simple conductivity measurements.

In practice, commercial conductivity probes

have either two or four electrodes, with the four-electrode

version being more resistant to fouling and other effects

that can cause degradation of the measurement. The electrodes

are made of nonreactive materials such as epoxy/graphite,

glass/platinum or stainless steel. The choice depends primarily

on the nature of the solution to be tested, but nearly any

commercial unit will be suitable for tap water.

Does Temperature Impact TDS Measurements?

One final complication is that the conductivity

of ions in water depends upon temperature. There are a number

of factors that cause this effect, but one big one is simply

that the ions are naturally moving around faster as they get

warmer. When the same numbers of ions are moving faster, the

apparent conductivity is increased. The relationship between

conductivity and temperature is complicated and dependent

on the solution being tested.

Pure water responds fairly linearly with

temperature, with its conductivity rising by 4.55% for every

degree centigrade (2.5% per degree Fahrenheit). Sodium chloride

solutions have a smaller change, about 2.12% per degree centigrade.

Tap and other natural waters have many different ions in them,

and such systems sometimes respond nonlinearly with temperature

changes, but not typically to as great of an extent as does

pure water.

For this reason, nearly all conductivity

meters simultaneously measure the conductivity and the temperature.

The internal electronics then take the temperature into account,

and normally provide a value that is "corrected"

to what the conductivity would be at a standard temperature

(25°C). Some use a fixed correction (for example, one

manufacturer uses 2.1% per degree centigrade, another uses

1.9% per degree centigrade). More expensive units often allow

the user to select the temperature coefficient (I'd use about

2-3% per degree centigrade for tap water). Others even allow

nonlinear corrections to be used. If your meter allows that,

I'd pick that option as it is likely a fixed correction that

is optimized for fresh water systems (often called nLF). Some

very advanced meters also allow nonlinear correction for ultrapure

water. If your meter uses either of these nonlinear corrections,

it will clearly say so in the provided manual.

In short, since conductivity meters typically

correct for temperature changes, the conductivity of the water

sample can be measured regardless of the temperature of the

sample.

What Do the Units "ppm" Mean?

The units of measurement that TDS meters

use are even more confusing than the name TDS. Conductivity

meters (including TDS meters) always work by first measuring

conductivity. Conductivity in solutions always has units that

relate to resistance. Often those units are mS/cm

(microsiemens per centimeter), but for solutions with higher

conductivity, mS/cm (millisiemens per centimeter) is typically

used (for example, normal seawater has a conductivity of about

53 mS/cm). For reference, the conductivity of totally pure

water is 0.055 mS/cm.

[[Aside: Often the purity

of very pure water is presented in units of resistance, or

Mohms (megaohms). In that case, totally pure water has a resistance

of 18 Mohms, which is just 1/conductivity in mS/cm.

Also, for curiosity, the highest known conductivity of an

aqueous solution is that for 31% nitric acid, at 865 mS/cm.]]

Unfortunately, TDS meters do not typically

provide a result in unambiguous conductivity units. They internally

convert their conductivity measurement into a different unit:

parts per million or ppm. Parts per million is the same as

mg/kg. So these devices are somehow converting the conductivity

unit into a weight based unit. The problem is that different

users and different devices can define that conversion differently.

If you choose a meter that reads in mS/cm,

then all of the concern about ppm units that is described

below can be eliminated. The Pinpoint

Conductivity meter is such a unit (Figure 2). Some devices

allow either unit to be displayed, although these are usually

more expensive, such as the Oakton

Con 200 (Figure 3).

Figure 2. The Pinpoint conductivity meter.

Figure 3. The Oakton Con 200 conductivity meter.

True TDS meters (that only give output

in TDS units, such as the Oakton

TDS Tester shown in Figure 4) typically convert the conductivity

reading into the ppm concentration of some salt that would

give the same measured conductivity. For example, it might

be set to give as its output the concentration of sodium chloride

(NaCl) that would give that same conductivity. So if the device

detected 447 mS/cm,

it might display that as 215.5 ppm, as that is the concentration

of sodium chloride that gives that same conductivity.

Figure 4. The Oakton TDS Tester.

Unfortunately, there is no single exact

conversion between conductivity and ppm NaCl as the conductivity

of a sodium chloride solution is not linear with concentration

(that is, 20 ppm NaCl is slightly less conductive than twice

that of 10 ppm NaCl, the reasons for which are beyond this

article, but in a sense, the more ions there are in solution,

the more they interfere with each other in terms of sensing

the voltage, and in terms of moving in response to it). Nevertheless,

for values in the range sensed by most TDS meters, a rough

conversion is that 1 ppm NaCl = 2.1 mS/cm.

Now the fun really begins. The problem

with such devices, at least when not carefully calibrated,

is that it is not clear whether it is referring to ppm of

sodium chloride equivalents, or to something else. Potassium

chloride (KCl) is actually used as the standard more often

than sodium chloride. Additionally, researchers often use

something called 442,

which is a mixture of sodium sulfate (40%), sodium bicarbonate

(40%) and sodium chloride (20%). The 442 mixture is designed

to mimic the ions often present in natural fresh water systems.

These systems all have slightly different

relationships between concentration (in ppm) and conductivity

(in mS/cm). Table

2 shows this relationship for some commercial conductivity

standards made by Oakton.

For many aquarium purposes, it may make little difference

whether the true value corresponds to 10 ppm NaCl or 10 ppm

442, but there is a 30-70% difference in the measured conductivity

and hence in the total ions present. Consequently, two

aquarists using different meters (which may use different

standards) may get substantially different results on the

same water. Of course, if you calibrate the meter yourself

(if that is possible, not all meters can be calibrated), instead

of accepting a factory calibration, then you eliminate this

concern since you know exactly what you calibrated with.

|

Table 2. Conductivity

and ppm values for various commercial standards made

by Oakton.

|

|

Model

# (bottles)

|

Conductivity

(µS/cm)

|

TDS

ppm KCl

|

TDS

ppm NaCl

|

TDS

ppm 442

|

|

WD-00653-23

|

23

|

11.6

|

10.7

|

14.74

|

|

WD-00653-16

|

84

|

40.38

|

38.04

|

50.50

|

|

WD-00653-47

|

447

|

225.6

|

215.5

|

300.0

|

|

WD-00653-18

|

1413

|

744.7

|

702.1

|

1000

|

|

WD-00653-15

|

1500

|

757.1

|

737.1

|

1050

|

|

WD-00653-27

|

2070

|

1045

|

1041

|

1500

|

|

WD-00653-20

|

2764

|

1382

|

1414.8

|

2062.7

|

|

WD-00653-89

|

8974

|

5101

|

4487

|

7608

|

|

WD-00606-10

|

12,880

|

7447

|

7230

|

11,367

|

|

WD-00653-50

|

15,000

|

8759

|

8532

|

13,455

|

|

WD-00653-32

|

80,000

|

52,168

|

48,384

|

79,688

|

|

Model

# (pouches)

|

|

|

|

|

|

WD-35653-09

|

10

|

4.7

|

4.8

|

7.0

|

|

WD-35653-10

|

447

|

225.6

|

215.5

|

300.0

|

|

WD-35653-11

|

1413

|

744.7

|

702.1

|

1000

|

|

WD-35653-12

|

2764

|

1382

|

1414.8

|

2062.7

|

|

WD-35653-13

|

15,000

|

8759

|

8532

|

13,455

|

Tips for Using TDS Meters

1. Always rinse the business end of TDS

and conductivity meters before and after each use with as

clean fresh water as you have available. The buildup of salts

will interfere with proper operation, and the carryover of

salts from one solution to another can skew the readings.

2. Do not touch or otherwise abrade the

electrode surfaces, except with a soft, nonabrasive cloth.

3. Clean the electrodes, when necessary,

by soaking the tip in acid (e.g., vinegar or diluted hydrochloric

acid (muriatic acid)) and then rinsing well in water. If it

is heavily fouled with organic material, soaking the tip in

alcohol or bleach may help. Gentle wiping with a soft, nonabrasive

cloth may also be acceptable.

4. If you care what the exact readings

mean, be sure to calibrate the meter using a commercial standard.

Some meters may require an exact standard, or any of several

standards with a preset value, so get the meter first and

see what you need. Home improvement, Halloween costumes, and more

on Menards Ad.

One standard is adequate. If all you care

about is whether the reading is zero or not (for testing water

purification systems), then calibration may not be important.

5. Nearly all conductivity (TDS) meters

have automatic temperature compensation over the range from

0 to 50ºC. Even the least expensive units usually do

this. If for some reason yours does not, the standard temperature

for taking readings is 25ºC. Just be aware that readings

in cooler temperatures will be artificially low if it is not

corrected (about 2-4% per degree centigrade).

6. Only very expensive meters have cell

constant adjustment. The "cell constant" is another

word for calibration, but is somewhat more sophisticated as

some units allow you to use different electrode assemblies

optimized for different types of solutions. For example, some

are optimized for low, medium, or high conductivities in the

solutions to be tested. The meter would have to know what

kind of electrode assembly it was attached to, if it were

allowed to be changed. Most TDS meters will not permit this

change.

7. If you are using a TDS or conductivity

meter to monitor the performance of an RO membrane, then the

measured value should drop by at least a factor of 10 from

the starting tap water. So, for example, if the tap water

reads 231 ppm, then the RO water should be less than 23 ppm.

In many cases, it will drop much more than that. Less of a

drop than a factor of 10 indicates a problem with the RO membrane.

8. If you are using a TDS or conductivity

meter to monitor the performance of an RO/DI system, then

the measured value should drop to near zero. Maybe 0-1 ppm.

Higher values indicate that something is not functioning properly,

or that the DI resin is becoming saturated and needs replacement.

However, that does not necessarily mean that 2 ppm water is

not OK to use. But beware that it may begin to rise fairly

sharply when the resin becomes saturated. Do not agonize over

1 ppm vs. zero ppm. While pure water has a TDS well below

1 ppm, uncertainties from carbon dioxide in the air (which

gets into the water and ionizes to provide some conductivity)

and the TDS meter itself may yield results of 1 or 2 ppm even

from pure water.

9. If you are using a TDS or conductivity

meter to monitor the saturation of limewater, then it will

have to be able to read as high as 10.5 mS/cm (about 9300

ppm of 442 equivalents). This linked

article describes how that is done.

10. If you are using a TDS or conductivity

meter to monitor the salinity of a marine aquarium, you will

have to be able to read up to about 53 mS/cm (about 53,000

ppm of 442 equivalents). I do not suggest trying to determine

salinity from diluted samples, as the conductivity of seawater

does not drop linearly with dilution.

11. You can measure the TDS of a water

sample in any way that is convenient given the water and the

meter being used. The primary consideration is that the entire

electrode assembly must be submerged in the sample without

a lot of bubbles or solids present between the electrodes.

So, for example, you cannot typically get a good reading by

holding it in a stream of tap water because air often gets

between the electrodes that way (resulting in an artificially

low reading).

I hope this information proves useful in

using your TDS meter successfully!

Happy Reefing!

|