| Introduction

The majority of unwanted organic wastes found in our aquariums

collect at the surface of a gas-liquid interface. These "surface-active"

materials, including fish wastes, uneaten food, and decomposing

matter are what we attribute to increasing our tanks pollution.

We associate this extra waste with increases in nuisance algaes,

cyanobacterial blooms, and having a generally unhealthy tank

appearance. Therefore, when we add new fish, and/or increase

the volume of foods in our tank, we hope to remove an equal

amount of potential pollution. The good news is we can reduce

some of these potential wastes by removing them from the water

before they cause problems. One method of removing organic wastes

from a fish tank is through foam fractionation (skimming).

The protein skimmer originated in the wastewater

treatment industry many years ago. It was used primarily to

reduce the organic load before the water reached the activated

sludge reactors. This technique exploits the affinity of organic

waste to adsorb to air bubbles. In basic terms, organic-waste-laden

aquarium water is reacted in a column of air bubbles, the

waste sticks in the foam, and the foam collected. Foam is

what is produced when one passes a gas through a liquid that

contains high levels of surfactants.

In the following sections of this article

I would like to explore the basics of protein skimmers (also

known as foam separators, foam fractionators, or air-strippers),

discuss why foam fractionation works, and describe a few of

the current skimmers which are commonly available to the hobby.

So what are we

trying to remove?

Fish poop, of course. Honestly, proteinacious waste only makes

up a small portion of what we are trying to eliminate. According

to Millero [1], the concentration of proteins found in natural

seawater (as amino acids) is about 0.02 to 0.25 ppm (20 to

250 ug/l). These make up 2-3% of the dissolved organic compounds

found in our tank water. However, data presented by Shimek

[2] in which 23 hobbyist's tanks were surveyed reported protein

concentrations of 0.00+ 0.00, suggesting that these tanks

were devoid of any detectable proteins. Other organic wastes,

which are more readily detectable, are primary and secondary

amines, some amino sugars, alcohols, and fatty acids. Lipids

(fats) were measured at 1.361 ± 0.940 ppm with a maximum

of 3.20 and a minimum of 0.00 in the same study [2]. So, then,

what are protein skimmers removing? More importantly, why

do we even call this device a "protein skimmer"

when there's no protein to remove?

Dissolved Organic

Compounds (DOCs)

DOCs are the waste molecules skimmers are designed to remove;

these are produced as byproducts from the breakdown of biological

materials. This pollution arises from not only the deliberate

input of foods in our tank but also from decaying organic

matter (bacteria, algaes, etc). DOCs are bipolar molecules;

these surfactants are attracted to air/water interfaces, i.e.,

bubbles. A bipolar molecule contains one or more atoms attracted

to air, and one or more atoms attracted to water. A skimmer

exploits this difference in the following manner:

"As an air bubble moves through

the column of organic-laden water, the electrically charged

protein molecules (which contain electrically polar and electrically

nonpolar regions) are attracted to the air/water interface

of the bubble. The polar regions of the molecule (made up

of nitrogens, oxygens, etc.) are attracted to the air/water

interface and these polar "tails" stick out away

from the air bubble into the water column. The nonpolar regions

stick out into the air bubble because it does not "like"

to be in contact with the polar solvent (i.e. water). If you

could look at this bubble under high enough magnification

down to the molecular level, the entire air bubble would look

like a fuzzy ball with protein tails and other electrically

charged tails sticking out from the surface of the air bubble.

The polar regions outside of the air bubble stabilize the

air bubble very much like a soap bubble in your kitchen sink

or your washing machine. This is the reason why foam begins

to build up at the surface of the skimmer. As the protein-laden

bubble reaches the top of the protein skimmer, the proteins

begin to accumulate which creates a stable foam bubble. These

stable foam bubbles take a long time to pop. Thus, the proteins

slowly are concentrated at the top of the skimmer where they

are slowly pushed through the "throat" of the protein

skimmer and into the collection cup."

This description, written by Shane Graber, can be found in

its entirety here.

The longer that the DOCs are in contact

with the bubbles, the more of them will attach to the bubbles,

the more of them will be removed. Longer contact times allow

for less adherent molecules to be attracted and "stuck"

to an air bubble. Other compounds besides DOCs can be removed

as well. These may be VOCs (volatile organic compounds), POC

(particulate organic compounds), uneaten fish food, trace

elements, secondary metabolites from soft corals, bacteria,

macro- and micro-planktons, coral eggs and sperm and other

similar compounds.

Okay, so how do

we make a protein skimmer?

Theoretical concerns VS reality

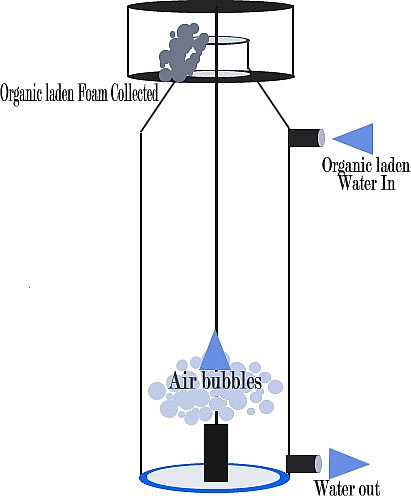

If a foam fractionator were constructed in its simplest form,

it would look like a tall tube in which tiny air bubbles are

injected into the bottom center. Waste laden water would be

pumped into this tube with the intent of the waste adhering

to the air bubbles. If you recall in the above DOC section,

air bubbles act as an adsorbent, and waste molecules are attracted

to this adsorbent and are removed from the water column as

foam. With this description, let's explore the parts of a

simple skimmer.

A skimmer has at least three parts:

| 1. |

The skimmer body, where

most of the contact between the DOCs and water takes place. |

| 2. |

The foam separation area,

or riser tube, where the organic laden foam is separated

from the water. |

| 3. |

A collection cup, where the foam spills

over the riser tube and is drained away.(image below)

|

The above description can take many shapes and forms, and

the myriad of hobbyist skimmers available on the market suggests

this is true. However, my basic description above doesn't

look like many of the skimmers on the market today, and this

is where hobbyists get confused. With so many skimmers on

the market, which one is the "best one" for their

tank? The bottom line is there is NO one best skimmer. Many

hobbyists are looking for the perfect skimmer, one that will

remove all the organic waste in the tank water, a skimmer

which is compact in size, inexpensive to run, and requires

virtually no maintenance. In reality, what skimmer to use

is truly a guessing game. What we do know is that different

skimmer designs equate to different levels of effectiveness

at removal of waste. The confusing part comes when hobbyists

are confronted with manufacturer's advertising, claiming their

skimmer is superior over all the rest because of some 'new'

skimming technology. Claims such as, "The "Cycloskim2000"

which is 18" tall, will easily skim your 100gal fish

tank, and only requires 1 watt of electricity to operate,"

are rampant in manufacturer's advertisements. So, how do we

separate what's truth and what's advertising? For me, one

of the least complicated ways to understand which skimmer

to buy is to understand a few of the theoretical basics of

skimming and then apply this theory into functional reality.

In chapter 9 of the textbook Aquatic Systems Engineering:

Devices and How They Function, P.R.Escobal 2000 [3] Escobal

presents a few theoretical concerns that should "shape"

the efficiency of a skimmer. These are presented in original

form in Table #1.

| 2nd Law: |

The bombardment rate (number

of times a clean air bubble bumps into a drop of water)

depends on the duration of the tank water exchange and

the diameter of the skimmer. |

| 3rd Law: |

Increased skimmer length

or height only raises the value of the absolute contact

time but does not affect the bombardment rate. |

| 5th Law: |

The airflow rate entering

a skimmer should produce a full upward blossom of bubbles

without excessive turbulence, and is theoretically determined

as a function of skimmer diameter, length, bombardment

rate and absolute contact time. |

| 6th Law:

|

The value of bombardment

rate within the skimmer, its length, diameter and airflow

must all be properly chosen for optimum operation. |

Table #1

Simplifying and summarizing these "skimming laws"

allows us to focus our efforts to ensure we have optimal skimming

(Table #2). This is a list of concerns, and there are four

parameters that need to be addressed.

|

Skimmer Design

Concerns

|

•

|

The water flow rate

through the skimmer |

|

•

|

The height of the

skimmer |

|

•

|

The amount of air

pumped into the reaction chamber of the skimmer |

|

•

|

The diameter of

the skimmer |

|

Table #2

| 1) |

For optimum skimming,

water flow thru the skimmer should be sufficiently slow

as to allow interactions of an air bubble and organic

waste. The best designs for this are skimmers that

employ water moving against the flow of bubbles. These

are called counter-current skimmers. However, slow is

a relative term. |

| 2) |

Make the skimmer reaction

chamber as tall as possible to maximize the contact time

that the water has with the air in the skimmer. Pump as

much air into the reaction chamber as possible.

The key to injecting air is twofold: a) maintaining the

smallest sized air bubbles, and b) reducing any potential

turbulence of the air bubbles in the skimmer reaction

chamber. |

| 3) |

The diameter of the

skimmer must be increased in proportion to the amount

of water being skimmed. The larger the amount of water

to skim, the wider the diameter of the skimmer should

be. |

Remember that these are theoretical concerns;

and often a theory is just that, a theory. Reality is often

times different. As an example, let's assume that you want

to build the most efficient skimmer for a 100 gal-reef tank.

Using the skimming laws above, the skimmer should have a five

to six foot tall, eight inches wide reaction column, with

a turnover of two tank volumes/day. It would have dense thick

foam consisting of 0.2 to 0.5mm bubbles, injected in a counter

current fashion against the water entry. So, while this might

be the most efficient skimmer, it is also, in my opinion,

impractical for many hobbyists. This is where we can put aside

the theory as directly written and understand some real world

examples.

Can sufficient skimming be achieved by

using a shorter, thinner skimmer or one that has a higher

flow rate? Yes. Will it be as efficient as our theoretically-defined

skimmer above? Maybe not, but it will be sufficient for the

needs of many hobbyists. Manufacturers of skimmers have gone

to great lengths to optimize their skimmer function and even

though many of the above "skimming laws" are not

met at face value, their skimmers work efficiently. In attempting

to bypass tall reaction column heights, manufacturers have

devised clever ways to lengthen the reaction time: the use

of triple pass flow, and downward air injection tubes of equal

length to reaction tubes which thereby effectively double,

or triple, reaction column lengths. Water swirling patterns

will also effectively increase reaction times. To maximize

bubble density, manufacturers have incorporated air-injecting

spray heads, venturi valves, and other foam generating heads

(such as a Beckett valve) into their designs. The use of a

foaming head effectively removes the requirement for airstones

and an air pump. When matched to a powerful water pump, many

of these foaming heads produce much larger quantities of air

than any airstone/air pump combination can achieve.

Quote: "If

you study Escobal, you will find that residence time, diameter

and air volume all have effects on skimmer operation. Nothing

in his book explains why the Hot-1 works at all, but users

like it." CWA46, Nashville, TN.

Let's examine a few of the skimmer types

available on the market today and how they are optimized to

skim efficiently.

Air

driven counter-current (CC) skimmers Air

driven counter-current (CC) skimmers

Air driven skimmers are the original type of skimmer designed

for the home aquarium, and fortunately they are one of the

most efficient. However, they also require the most frequent

maintenance, and can be costly. These skimmers use wooden

air diffusers and a powerful air pump to produce their bubbles.

These skimmers have excellent foam volume and consistency

when operated with new (unclogged) airstones. According to

Theil [4], the minimum recommended height of an air driven

CC skimmer is 28", and this skimmer should have two to

three air woods (airstones) for every 4" of skimmer width.

Therefore, a 6" diameter skimmer should have four to

six air woods. Depending on the organic load of the tank,

airstones should be replaced monthly to every two months,

and air pump diaphragms checked and replaced when weakened.

His reasoning for a minimum height of a CC skimmer is due

to the fact that the water and air bubbles must interact over

a set distance and time, and a skimmer shorter than 28"

does not meet these criteria. Long-time hobbyists consider

this skimmer type to produce the most consistent quality foam.

Interestingly, this skimmer style strictly adheres to our

"skimming laws," and when tuned properly it seems

to yield the best results. This is a common skimmer for DIY'ers,

as this skimmer is easy to construct and requires minimal

construction skills.

Venturi skimmers

A venturi skimmer uses a venturi injector to create air bubbles.

These skimmers tend to be shorter than air driven CC skimmers,

and require a powerful pump to drive the venturi valve. For

an explanation of how a venturi valve works, see the explanation

box found in this article [5]. One reason why venturi skimmers

are often utilized in home aquariums is that venturi valves

produce tremendous amounts of bubbles. One of the more common

venturi injectors is a Mazzei®

injector  (image

right). When matched with a high performance pump, these injectors

create large volumes of fine bubbles. The bubble quality tends

to be very good, and this aerated mixture is often injected

into a reaction chamber in a swirling fashion to maximize

contact times. A 1" Mazzei® injector can pull up

to 240cubic ft/hr of air. The Lifereef

VS2 is an example of a skimmer which utilizes this injector.

Another type of (image

right). When matched with a high performance pump, these injectors

create large volumes of fine bubbles. The bubble quality tends

to be very good, and this aerated mixture is often injected

into a reaction chamber in a swirling fashion to maximize

contact times. A 1" Mazzei® injector can pull up

to 240cubic ft/hr of air. The Lifereef

VS2 is an example of a skimmer which utilizes this injector.

Another type of  venturi

skimmer is a Beckett-head skimmer. The Beckett foam generating

spray head is designed for increasing the amount of air that

is mixed into the water. Skimmers incorporating a Beckett-head

often utilize the Beckett in a higher position than the water

level and this extra distance allows for an increase in reaction

time. Additionally, manufacturers have begun to tangentially

inject aerated water into swirling patterns, which also increases

contact time. What is most obvious with a Beckett-head is

the density and consistency of the foam; it far exceeds any

of the other current aeration strategies. The Precision Marine

BulletXL skimmer is an example of one utilizing this injector(image

left). venturi

skimmer is a Beckett-head skimmer. The Beckett foam generating

spray head is designed for increasing the amount of air that

is mixed into the water. Skimmers incorporating a Beckett-head

often utilize the Beckett in a higher position than the water

level and this extra distance allows for an increase in reaction

time. Additionally, manufacturers have begun to tangentially

inject aerated water into swirling patterns, which also increases

contact time. What is most obvious with a Beckett-head is

the density and consistency of the foam; it far exceeds any

of the other current aeration strategies. The Precision Marine

BulletXL skimmer is an example of one utilizing this injector(image

left).

Downdraft™ skimmers

The downdraft™ skimmer is designed quite differently

from all other skimmers; it utilizes a jet of water sprayed

at high velocity into a column containing bio-balls. This

column contains media that effectively disrupts the jet spray

and forms bubbles. After the bubbles flow through this "bioball

column" they enter a sump box, and are deflected upwards

to the foam collection riser in the neck of the skimmer.

In this skimmer configuration, the lengthy water path through

the bioball column, across the sump, and up through the neck

of the skimmer, effectively increases the reaction time. Additionally,

the disruption of the jet spray results in copious amounts

of bubbles and foam. These skimmers require a very powerful

pump to run correctly, and tend to be fairly large units.

A skimmer incorporating this design is the ETSS®

Gemini 800.

Aspirating impeller skimmers (Air Shredding)

This style skimmer offers a unique twist on an inexpensive

aeration system. Essentially, directing air into the impeller

cavity of a powerhead or small pump creates bubbles. The regular

impeller (Figure #7b below top), a specialized needle wheel

(Figure #7c below left), or pegged wheel (Figure #7d below

right) then finely chops up these air bubbles into very fine

bubbles like those found in an airstone driven skimmer. These

units are unique in that they have a very slow water flow,

generate large amounts of foam, and are cheap to run because

they use low power pumps. A concern which has arisen with

these skimmers is the durability of these specialized impellors.

Because these needlewheel impellors place the weight load

on the periphery of the impellor (and not close to the central

shaft), these impellors have higher failure rates than do

normal vaned impellors. Two skimmers that utilize specialized

needlewheels are the Turboflotor 1000 and the Euro-Reef.

A skimmer that utilizes a traditional impellor in an air shredding

strategy is the German Klaes Skimmer, which is reviewed here.

|

|

|

(Figure #7b)

Regular impeller

|

|

|

|

(Figure #7c)

Specialized needle wheel

|

(Figure #7d)

Pegged wheel

|

|

To Summarize the Current Skimmers:

Air driven counter-current: low water flow, good foam

production (with new air stones), good bubble size, maximum

contact times (with taller units), frequent maintenance and

requires frequent water height adjustments (called tuning).

Venturi: good water flow, good foam production, moderate

contact time, requires a powerful pump, valve tends to clog

(Lifereef has a self-cleaning venturi

valve).

Beckett-head skimmer: high water flow, maximum bubble

production, moderate contact time (swirling patterns will

increase this), requires a very powerful pump, Beckett-head

requires cleaning.

Downdraft™: good water flow,

excellent bubble production, excellent contact time. Units

tend to be tall and bulky (the ETSS 1000 is over 60”

tall), require powerful pumps to create air bubbles.

Aspirating skimmer: low to moderate water flow, good

foam production, good bubble size, excellent contact time,

cost-efficient, requires specialized impellor or needlewheel.

The needlewheel impellors have been shown to be a weak point.

A few words about maintaining skimmers: to ensure optimal

skimming, periodically clean the skimmer. Design of the Spring

and Summer in furniture in

Amart Catalogue this week. Empty the collection

cup frequently, and wipe clean the organic buildup that collects

around the body and neck of the skimmer  (image

left). This organic sludge is what the skimmer removes from

the water and this material shouldn't be allowed to fall back

into the water. Clean the air valves often, and remove any

built-up salt crust or particulate matter clogging the air

intake. Also, be aware that small snails and rock fragments

may become caught in the restrictions of many venturi valves

and pump intakes and must be removed if the skimmer is to

perform at peak efficiency. If airstones and an air pump are

being used, ensure its bubble production is optimal, replace

the airstone at regular monthly or bimonthly intervals and

check the air pump diaphragm to ensure maximal air is being

produced. Deep skimmers require consistently high pressure

from the pump diaphragm to work properly. If the skimmer requires

a water pump to generate bubbles, make certain the pump drives

the venturi or other air injection device at maximum efficiency;

weak pumps cause skimmers to work poorly. (image

left). This organic sludge is what the skimmer removes from

the water and this material shouldn't be allowed to fall back

into the water. Clean the air valves often, and remove any

built-up salt crust or particulate matter clogging the air

intake. Also, be aware that small snails and rock fragments

may become caught in the restrictions of many venturi valves

and pump intakes and must be removed if the skimmer is to

perform at peak efficiency. If airstones and an air pump are

being used, ensure its bubble production is optimal, replace

the airstone at regular monthly or bimonthly intervals and

check the air pump diaphragm to ensure maximal air is being

produced. Deep skimmers require consistently high pressure

from the pump diaphragm to work properly. If the skimmer requires

a water pump to generate bubbles, make certain the pump drives

the venturi or other air injection device at maximum efficiency;

weak pumps cause skimmers to work poorly.

In Summary

Protein skimmers can be an effective method

in reducing the problems related to waste accumulation in

our tanks. The application of skimmers have been associated

with reduced waste (reduction of DOCs), reduced algal growth,

and increased water quality. Many of the present  skimmers

on the hobbyist market are too small (height and diameter)

and/or underpowered to effectively remove sufficient amounts

of organic waste. As a rule of thumb, taller skimmers tend

to work better than short, squat ones. The hobbyist needs

to ensure bubble production is maximized (smaller bubbles

work better than big bubbles), and consequently, the water

in the reaction column should be milky white in appearance.

The foam produced in the skimmer should be continually moving

up towards the collection cup so that is being collected and

removed from the system. One final word on skimmate consistency:

this topic is often a subject of debate (i.e., thick, mud

colored, and dry versus watery and iced-tea colored (image

above right)), and it would bear further discussion in another

article. I'll leave the topic for now by saying: you want

to collect skimmate (any skimmate), and any skimmate is better

than no skimmate at all. skimmers

on the hobbyist market are too small (height and diameter)

and/or underpowered to effectively remove sufficient amounts

of organic waste. As a rule of thumb, taller skimmers tend

to work better than short, squat ones. The hobbyist needs

to ensure bubble production is maximized (smaller bubbles

work better than big bubbles), and consequently, the water

in the reaction column should be milky white in appearance.

The foam produced in the skimmer should be continually moving

up towards the collection cup so that is being collected and

removed from the system. One final word on skimmate consistency:

this topic is often a subject of debate (i.e., thick, mud

colored, and dry versus watery and iced-tea colored (image

above right)), and it would bear further discussion in another

article. I'll leave the topic for now by saying: you want

to collect skimmate (any skimmate), and any skimmate is better

than no skimmate at all.

For additional infomation see: www.proteinskimmers.com

|