|

This article describes

the thought processes, and the construction of the Precision

Marine Bullet skimmer. I have been very fortunate to be involved

in this project, from its conception to the final production

models. Hobbyists need to see and understand what actually

goes into building a skimmer, and that is my reason for presenting

this report. The construction materials, testing, and final

optimization of the unit, adds up to a serious commitment

of time, effort, and money. I must thank the owner of Precision

Marine, Mike S. for his commitment to the project, for without

his expertise in constructing these skimmers, and providing

the raw material, this project would never have gone forward.

Evolution of a Skimmer

Background

Back in August of '98, another avid hobbyist, James Wiseman,

and I had been discussing our fish tanks. In particular, we

had focused on the role of feeding large amounts of food in

a closed system.  One

concern that kept arising was how our tanks would

handle this nutrient load. The outcome of the discussion was

that if we wanted to feed heavily, we would have to find a

way to export the extra waste. One possible solution to this

problem is to eliminate the extra nutrients via skimming (foam

fractionation). Both of us had used traditional air-powered

or counter-current skimmers and were disappointed by their

lackluster performance. We thought a more efficient, large

water-processing skimmer might be a good solution. Within

a few days, James sketched a skimmer design outlining what

we thought was a good compromise of compactness, utility,

and performance. He had placed structural limits on the design

of this skimmer that were dictated by our large tanks. As

neither of us wanted an external skimmer, it had to fit under

a 30" cabinet. To save under-cabinet space, we wanted

the skimmer to reside in our sumps, which were less than 12"

wide. A third consideration was that it had to have high turnover

rates and water processing ability. Therefore, the skimmer

had to have a configuration that would allow for long contact

times, with fast and non-restricted flow-through. One

concern that kept arising was how our tanks would

handle this nutrient load. The outcome of the discussion was

that if we wanted to feed heavily, we would have to find a

way to export the extra waste. One possible solution to this

problem is to eliminate the extra nutrients via skimming (foam

fractionation). Both of us had used traditional air-powered

or counter-current skimmers and were disappointed by their

lackluster performance. We thought a more efficient, large

water-processing skimmer might be a good solution. Within

a few days, James sketched a skimmer design outlining what

we thought was a good compromise of compactness, utility,

and performance. He had placed structural limits on the design

of this skimmer that were dictated by our large tanks. As

neither of us wanted an external skimmer, it had to fit under

a 30" cabinet. To save under-cabinet space, we wanted

the skimmer to reside in our sumps, which were less than 12"

wide. A third consideration was that it had to have high turnover

rates and water processing ability. Therefore, the skimmer

had to have a configuration that would allow for long contact

times, with fast and non-restricted flow-through.

The

initial sketch outlined a step-shaped, tall rectangular box

that had a divider running down the center (Fig 1).

On the right side of the skimmer box was the water inlet where

the air/water mixture entered the chamber. This mixture would

run down the length of the right side to the bottom, where

a small baffle directed the mixture to the top of the left

side. On the top left side, we attached an interchangeable

neck and collection cup. The total height of this skimmer

was 18" on the right and 14" on the left. The skimmer

was 9" long and 4" wide. The total distance that

the processed water would travel was 28", which was equivalent

to a 28" tall reaction chamber if the skimmer was vertical.

This distance was more than sufficient for our purposes.

As an important aside, Chris

Paris, a Ph.D. student working on wastewater processing,

posted his ideas on how to increase the effectiveness of current

skimmer technology. In his writings, he presented complex

equations that described the fluctuating parameters that occur

in an air/water mixture when one increases the amount of air

mixed into a constant volume of water. Also, he discussed

parameters to increase contact time between an air bubble

and a waste molecule. The bottom line was that he presented

a strong argument for the use of more efficient aeration devices

(foam generators), as one way to create a skimmer with a high

waste removal capability. We found Chris Paris's proposal

of using the patented Beckett pond foaming head [See Explanation

Box Below] as a possible aeration device, very intriguing.

This was just the foam generator we needed for our new skimmer.

The Beckett valve possessed many favorable features such as

maximum air intake, extended water processing time and compact

size, which we could exploit in our design.

Once we had decided on using a Beckett head as an aerator,

the skimmer plans began to fall into place. Since neither

James nor I had much experience at working with acrylic or

building a skimmer, we decided to approach Mike at Precision

Marine. Mike is a long time local Houston resident and an

expert skimmer manufacturer. At the time, Precision Marine

had many airstone driven counter-current skimmers (the PM-AP

line), as well as recirculating counter-current traditional

venturi skimmers (the PM-CV-line). These skimmers, and his

product line, were well established in the aquarium trade.

We approached Mike with the idea of a new skimmer utilizing

the Beckett head, and presented him with our rough sketch

and our list of limitations. Once Mike was sold on the idea

(thank God for margaritas), he constructed the first working

prototype based directly on James' sketch (Fig 2).

Mike's

first step in building our skimmer was to create a screw-on

containment chamber for the Beckett head (Fig 3). The

modular design allowed for two features: 1) we could mount

the Beckett head onto any of the test skimmers, and more importantly,

2) the containment chamber allowed a defined amount of air

to enter the Beckett head. From the literature and from Chris

Paris's writings, it was clear that a Beckett valve, which

was unrestricted to air, sucked in air at rates that were

detrimental to stable foam formation, since excess air resulted

in large bubble formation, and  violent

water movement from the outlet. violent

water movement from the outlet.

As

a way to reduce bubble size ("tighten the bubbles"),

and provide a more consistent bubble output, we would have

to restrict the amount of air entering the Beckett head. One

way of restricting air is to create a surrounding (containment)

chamber, which has only 1 air opening (Fig 3, top panel).

The top and bottom of the Beckett are sealed off to air, and

only allow water to pass through (Fig 3, lower panels).

Air enters through a single side hole, in which a user-adjustable

needle valve is attached. This needle valve controls the amount

of air that enters the Beckett. This containment unit was

affectionately labeled the Beckett 'bullet', due to its rounded

shape (Fig 3). Once this containment chamber was built,

it was attached to the original skimmer, and our first working

prototype was tested.

Prototypes galore

As an initial test of the Beckett head (actually to prove

to ourselves that this was the best foaming head), we decided

to add the Beckett bullet on a skimmer system that we were

quite familiar with. We attached the Beckett bullet to a downdraft

skimmer; the downdraft design is a well-established skimmer

technology and works efficiently with ETS's patented spray

technology. In this first test, we sought to determine foaming

(aeration) quality, and to measure water flow. Since it was

unclear which pump would work the best with the Beckett bullet,

we tested the bullet/downdraft combination with both a Rio

3100 powerhead (900gph) and a Mak4 pump (1200gph). Our first

observation was that air intake was substantial, but with

obvious differences between the two pumps. With the low-pressure

pump (Rio3100), the bubbles were visibly bigger, there were

fewer bubbles (the water was grayish), and the water exiting

the bullet was violent. However, it did foam, but the foam

was interrupted and unstable. Using the high performance pump

(Mak4), we observed substantially better results. The bubbles

were smaller in comparison ("tighter"), the aerated

water was the color of milk (many more bubbles), and the water

leaving the exit tube was fast, but calm. Interestingly, tests using both pumps resulted

in foam formation within 10-30 minutes, but the foam climbed

higher and was denser using the Mak4 pump. Since this was

only a preliminary test, the Beckett bullet performed as good

as we had anticipated.

fast, but calm. Interestingly, tests using both pumps resulted

in foam formation within 10-30 minutes, but the foam climbed

higher and was denser using the Mak4 pump. Since this was

only a preliminary test, the Beckett bullet performed as good

as we had anticipated.

This is when things got interesting. Over the next weeks,

Mike built a few working models of the skimmer which we had

outlined for him. These prototypes (Fig 4) were tested

using the screw-on Beckett bullet powered by either the Rio

3100 pump or the Mak4 pump. Our first observations were, once

again, that pump pressure differences were significant. It

had become quite apparent that weak pumps would not make consistent

bubble size, and this resulted in "burping" of the

air/water mix. After we resolved the pump situation, the next

issue appeared: the Beckett head was so efficient at aerating

water, that air leaving the bullet rapidly expanded in the

entry chamber. This resulted in pressurizing the reaction

chamber and forcing all the water out. This problem was not

observed during the downdraft test, but to our dismay was

an inherent problem with our step-shaped reaction chamber.

Fortunately, there was an easy fix.

We focused on efficiently moving air through the skimmer,

and displaced the water baffle at the  bottom

center of the reaction box. Displacing the center baffle forced

the air/water mix away from the downside, diverting it upward

towards the collection cup. This simple fix allowed for the

rapid passage of expanded air, and solved our pressurizing

problem. This new design resulted in the angular step-shaped

"Bigfoot" skimmer (Fig 4, 4th and 5th unit

from left). The Bigfoot skimmer was an excellent test model.

It was compact, contained over 30" of mixing distance,

and allowed air and water to rapidly move through it. However,

the curvature was not conducive to mass production of the

unit. {Author's note: I personally like the look}. Using the

information gleamed from the Bigfoot shape; we felt we were

one step closer to a final design. We learned that a displaced

baffle was required when using a direct injection scheme [see

explanation box below]. Furthermore, water diverted from

the baffle would foam directly adjacent to the water inlet.

Mike made 4 additional models (Fig 4, farthest right

unit) with differently shaped diverter baffles, such as circular

diverters. This circular diverter allowed for uniform spread

of the water mix (Fig 5). However, none of these uniquely

shaped diverters prevented "burping" or moving the

air/water mixture any more efficiently than the original displaced

baffle design. bottom

center of the reaction box. Displacing the center baffle forced

the air/water mix away from the downside, diverting it upward

towards the collection cup. This simple fix allowed for the

rapid passage of expanded air, and solved our pressurizing

problem. This new design resulted in the angular step-shaped

"Bigfoot" skimmer (Fig 4, 4th and 5th unit

from left). The Bigfoot skimmer was an excellent test model.

It was compact, contained over 30" of mixing distance,

and allowed air and water to rapidly move through it. However,

the curvature was not conducive to mass production of the

unit. {Author's note: I personally like the look}. Using the

information gleamed from the Bigfoot shape; we felt we were

one step closer to a final design. We learned that a displaced

baffle was required when using a direct injection scheme [see

explanation box below]. Furthermore, water diverted from

the baffle would foam directly adjacent to the water inlet.

Mike made 4 additional models (Fig 4, farthest right

unit) with differently shaped diverter baffles, such as circular

diverters. This circular diverter allowed for uniform spread

of the water mix (Fig 5). However, none of these uniquely

shaped diverters prevented "burping" or moving the

air/water mixture any more efficiently than the original displaced

baffle design.

The Final Shape Arrives

The box-shaped mixing chamber was a natural evolution of the

Bigfoot's curves, but without the requirement for elaborate

shapes, which created problems for the mass production of

the unit.  Next,

we required an area where the foam would accumulate and stabilize.

Mike incorporated a clear cast acrylic reaction column, 6"

tall by 6" wide, to replace the collection side of the

Bigfoot. However, incorporating this column required the reaction

box to be wider than we had hoped. Next,

we required an area where the foam would accumulate and stabilize.

Mike incorporated a clear cast acrylic reaction column, 6"

tall by 6" wide, to replace the collection side of the

Bigfoot. However, incorporating this column required the reaction

box to be wider than we had hoped.

The final box measured 6" wide and

10" long. The inlet side where the Beckett bullet was

attached was removed, and replaced by a single piece of PVC

(Fig 6). The reaction column was fitted with a threaded

flange, which permitted multiple sizes and shapes of collection

cups to attach onto it. This final skimmer fulfilled our initial

design criteria. It was compact, it would fit sideways into

a 12" wide tank, and the total height was 24", including

a 10" tall collection cup with the restrictor neck. Finally,

after 12 prototypes, we had a final design. However, the skimmer

was not complete without finalizing the perfect neck size,

collection cup setup, and exhaust port. The exhaust port is

critical in determining the volume of escaping air, in so

much as an inadequately sized exhaust port may exert backpressure

in the skimmer, reducing its efficiency. Unfortunately, the

determination of the collection cup size and the exhaust port

diameter was done empirically.

Mike constructed a series

of necks and cups with varying heights, widths, and exhaust

port sizes (Fig 7). Then, each neck was added to a

test skimmer, and monitored to determine airflow, the neck's ability to support and produce dry foam,and the ability

to project this foam over the neck. The final design was a

compromise between sufficient airflow through the skimmer,

and our height limitations. The first working models were

built in ABS plastic and were tested on both of our tanks

(Fig 8). As a test of each configuration's water processing

ability, we measured and compared the volume of water going

into the skimmer, versus the volume of water exiting the skimmer.

Utilizing a Mak4 pump to power the Beckett bullet, we measured

approximately 1200gph in and 500gph out. As a point of reference

for comparison, we used a Mak4 pump to drive an MTC HSA1000

skimmer (another Beckett head skimmer), and noted it had an

output of 450gph.

neck's ability to support and produce dry foam,and the ability

to project this foam over the neck. The final design was a

compromise between sufficient airflow through the skimmer,

and our height limitations. The first working models were

built in ABS plastic and were tested on both of our tanks

(Fig 8). As a test of each configuration's water processing

ability, we measured and compared the volume of water going

into the skimmer, versus the volume of water exiting the skimmer.

Utilizing a Mak4 pump to power the Beckett bullet, we measured

approximately 1200gph in and 500gph out. As a point of reference

for comparison, we used a Mak4 pump to drive an MTC HSA1000

skimmer (another Beckett head skimmer), and noted it had an

output of 450gph.

|

How

Does it Work?

Why a Beckett head?

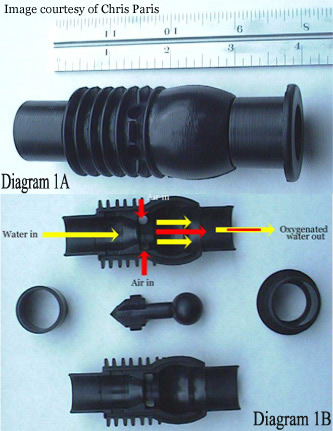

The Beckett 1408 pond foaming aeration head (Diagram

1A, top panel): The background on this head is well

described in the literature and its application for

aerating fish and farm ponds is well established. For

the purpose of this article, I will briefly describe

its background and offer a short description of how

it works. This  information

will play an important role in the design of the skimmer

and its utility in a home skimmer. Background: This

plastic (or metal) aeration head was designed to disrupt

surface tension on farm and fishponds allowing for highly

oxygenated water. It accomplishes this by mixing tremendous

amounts of air into pumped water. This air/water mix

is then sprayed into the air as a fountainhead. information

will play an important role in the design of the skimmer

and its utility in a home skimmer. Background: This

plastic (or metal) aeration head was designed to disrupt

surface tension on farm and fishponds allowing for highly

oxygenated water. It accomplishes this by mixing tremendous

amounts of air into pumped water. This air/water mix

is then sprayed into the air as a fountainhead.

The Beckett head was a novel design and a radical interpretation/modification

of a traditional venturi valve (Diagram 2). The familiar

traditional venturi valve has a single air intake (called

a pitot tube). Essentially, pressurized water enters

the injector inlet, it is constricted (by passing through

a restriction) toward the injection chamber and changes

into a high-velocity jet stream. The increase in velocity

through the injection chamber results in a decrease

in pressure in the injector body. When a sufficient

pressure difference exists between the inlet and outlet

ports of the injector, a vacuum is created inside the

injector body, which initiates suction through the suction

port. At this point air is literally sucked into the

vacuum space. As the jet stream is diffused toward the

injector outlet, its velocity is reduced and it is reconverted

into pressure energy (but at a pressure lower than injector

inlet pressure), and the "microbubbles" are

produced. In comparison, a Beckett head is a circular

3D version of a traditional venturi (Diagram 1B,

bottom panel). The designer of the Beckett utilized

the same concept of forcing water through a restriction.

However, in this application, the restriction is located

right before a large three-dimensional ball. A spike-

shaped divider evenly restricts the water stream over

the ball, and focuses the water under the four air intakes,

evenly spaced at ninety degrees apart. Water traveling

past the spike and around the ball, results in air being

drawn in from the four intakes. Once past the ball,

the air/water mix rapidly expands and creates microbubbles.

However, in comparison to the traditional venturi, the

Beckett head amplifies the amount of air drawn in. Due

to the design of the valve, we observed a significant

increase in the amount of bubbles created. Additionally,

the size of the bubbles appeared much smaller than what

we observed while using a traditional venturi valve.

Argos Catalogue

includes a wide range of electronics such as TVs and Smartphones.

If I have explained this adequately, you should understand

that bubble generation from the Beckett head is solely

dependent on the force of water through it: the stronger

the push (i.e., pump pressure) through the Beckett,

the more consistent the water stream flows over the

mixing ball. Faster water movement through the Beckett

head results in increased air intake and smaller bubble

formation, so a combination of a strong and powerful

pump will provide the best end result.

Beckett heads are designed for use in an end-terminal

application. As  described

above, Beckett valves were designed to sit on the end

of a PVC pipe and have water forced through them like

a fountain. These valves do not withstand the backpressure

of being under water, and consequently, for the most

efficient air intake, there should not be any backpressure

on the outflow of the head. This also provides an indication

as to how we can best utilize the Beckett to maximize

air intake. Maximum air intake and performance can be

obtained by placing the air intakes of the Beckett head

at a level which is higher than the water level in the

skimmer. Elevating the Beckett head on a small piece

of PVC will often achieve this result. described

above, Beckett valves were designed to sit on the end

of a PVC pipe and have water forced through them like

a fountain. These valves do not withstand the backpressure

of being under water, and consequently, for the most

efficient air intake, there should not be any backpressure

on the outflow of the head. This also provides an indication

as to how we can best utilize the Beckett to maximize

air intake. Maximum air intake and performance can be

obtained by placing the air intakes of the Beckett head

at a level which is higher than the water level in the

skimmer. Elevating the Beckett head on a small piece

of PVC will often achieve this result.

Tangential injection or direct

injection

Tangential injection (Diagram 3 left side) allows

the air/water mix to be injected at a tangent (angle)

into the reaction chamber. The most common tangential

injection method is to inject from or near the bottom,

facing up toward the inside wall of the reaction chamber.

This results in a beneficial swirling effect that effectively

increases contact time. The most important benefit of

using tangential injection is that  lower

performance pumps can be used to drive the Beckett head.

This is due to the fact that bubble inconsistencies

do not directly affect water in the reaction chamber,

as these bubbles are gently spilled into the reaction

chamber. Skimmers that utilize this injection method

are: the Precision Marine BulletXL, Marine Technical

Concepts (MTC) HSA250, and the Aerofoamer skimmers. lower

performance pumps can be used to drive the Beckett head.

This is due to the fact that bubble inconsistencies

do not directly affect water in the reaction chamber,

as these bubbles are gently spilled into the reaction

chamber. Skimmers that utilize this injection method

are: the Precision Marine BulletXL, Marine Technical

Concepts (MTC) HSA250, and the Aerofoamer skimmers.

The main benefit of direct injection (Diagram 3,

right side) is that it allows for a shorter reaction

chamber. However, this injection method also requires

a strong water pump, as foam formation in the water

column can be disrupted by bubble inconsistencies and

"burping." A skimmer which uses this direct

injection technique is the Bullet skimmer. Another directly

injected skimmer is the MTC HSA1000. In its design,

the manufacturer has decided to lengthen the reaction

chamber by utilizing a long downflow tube; the outflow

of water is then diverted upward, which essentially

doubles its reaction chamber length.

|

Image Legend

Fig 1. Cartoon

of James Wiseman's sketch. 1)-water inlet; 2)-"downside"

area of initial air/water mixing; 3)- mixing area "reaction

area"; 4)- water diverter baffle; 5)-drain outlet; 6)-"upside"

collection side where foam coalesces and stabilizes; 7)-interchangeable

collection cup and neck.

Fig 2.

A working prototype of the skimmer taken from James' sketch.

Fig 3.

The "Bullet" containment chamber. Top panel: this

is a completed containment chamber. Shown is the user adjustable

air valve (white/blue) the Bullet chamber with single air

intake hole. The bottom of the chamber faces left, and has

a 1' screw thread. The water inlet (top of the Bullet) faces

right. Lower panels: Left side, looking down into a Beckett

Bullet (note the spike divider and its four diverters); Right

side, looking up into the bottom of the Bullet (note the rounded

surface of the ball).

Fig 4.

A few of the skimmer prototypes. Note that all skimmers have

a 1" screw-on adapter on the inlet (to attach the Beckett

Bullet) and a universal flange with screw threads on the collection

side which allows a quick interchange of any sized collection

cup and neck.

Fig 5.

Circular diverter.

Fig 6. A

line up of different sized and shaped collection cups with

restriction necks.

Fig 7. The

down tube. Note that the Beckett Bullet threads onto the top.

Fig 8. The

finished product, a working Bullet2 prototype.

|